North American Clutch & Driveline

Rockford, Illinois

Phone: (800) 383-9204

(815) 282-7960

Fax (815) 282-9160

www.naclutch.com

36

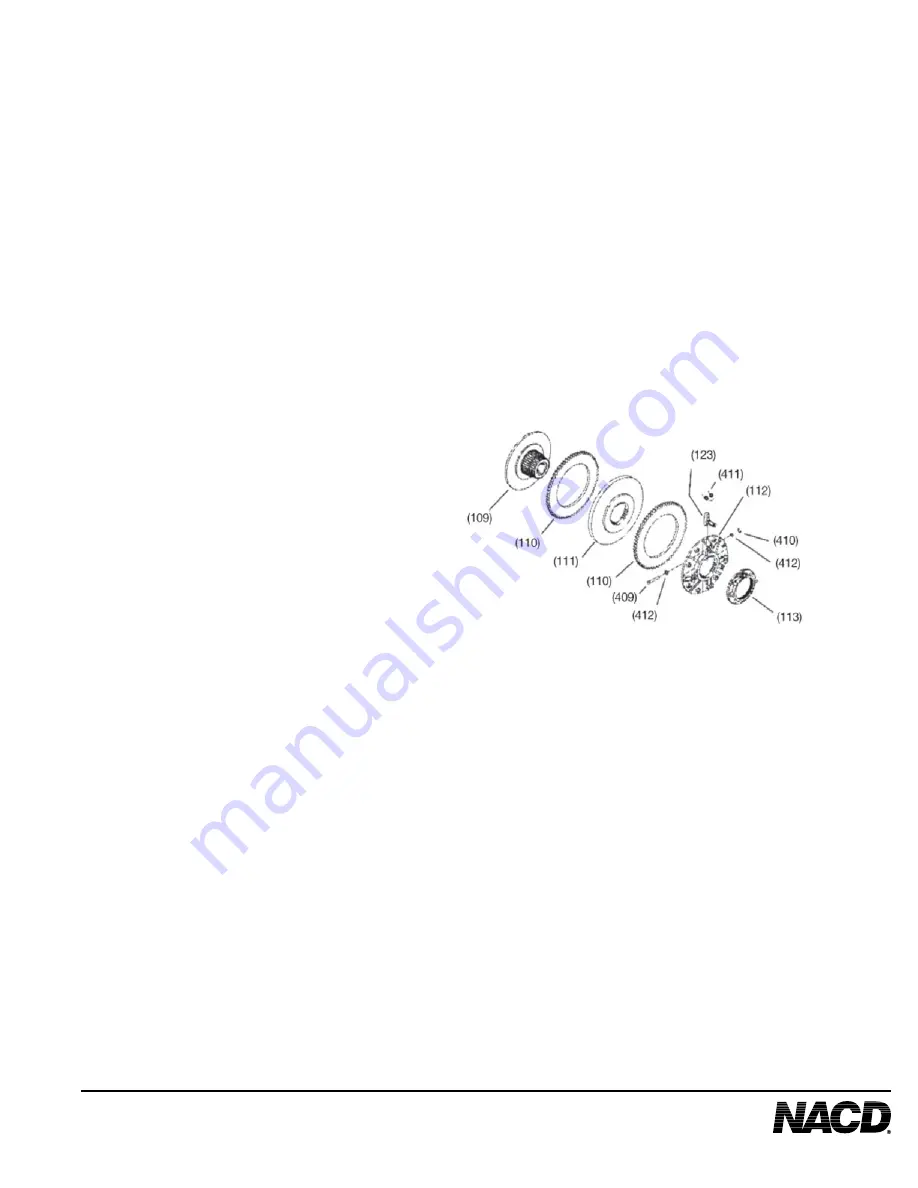

9.4.2 Rotate the adjusting ring (113) counterclockwise to remove it from the clutch

body

Note: Do not disassemble the adjusting ring assembly. If the unit needs to be repaired,

it must be serviced as an assembly. Individual components of the adjusting ring

assembly are not sold separately.

9.5 Complete the disassembly of the clutch.

9.5.1 Lift the pressure plate assembly (112) from the clutch body (109).

9.5.2 Note the direction the clevis pins (409) are installed so they can be reinstalled

in the same direction. Remove retainers (410), washers (412), and clevis pins (409) to

Seperate the levers and lever springs (411) from the pressure plate (112).

10.0 INSPECT THE CLUTCH COMPONENTS

10.1 Clutch Body

10.1.1 Friction surface must not have heat cracks, must be smooth and must be flat

within .005” (.127 mm.).

10.1.2 Splines must not have wear marks exceeding .003” (.076 mm.) depth due to

wear from the pressure plate or center plate.

10.1.3 Keyway must not be worn.

10.1.4 Tapered bore must fit snugly and securely on shaft.

9.5.3 Remove the facing plate (110).

9.5.4 (2 plate and 3 plate clutches only):

Remove the center plate(s)

(111) and the remaining facing plates.

Note: 14” HD(DP) clutches (2 plate) contain

a total of two (2) facing plates and one (1)

center plate. 14" HD (TP) clutches (3 plate)

contain a total of three (3) facing plates and

two (2) center plates.