2201Q4JE-MY-C9-N_2018.01.

Chapter 5 Maintenance and Inspection

Compound 2-stage Screw Compressor

4032**C

5.5 Reassembly

5-39

5.5.4 Installing the Rotors

The rotor must be sufficiently reworked. If any slight flaw is observed on the shaft surface in the area of

attaching the bearing and mechanical seal assembly, use a sand paper to correct and finish the surface.

After finishing the surface to attach the seal, apply protective tape on the surface.

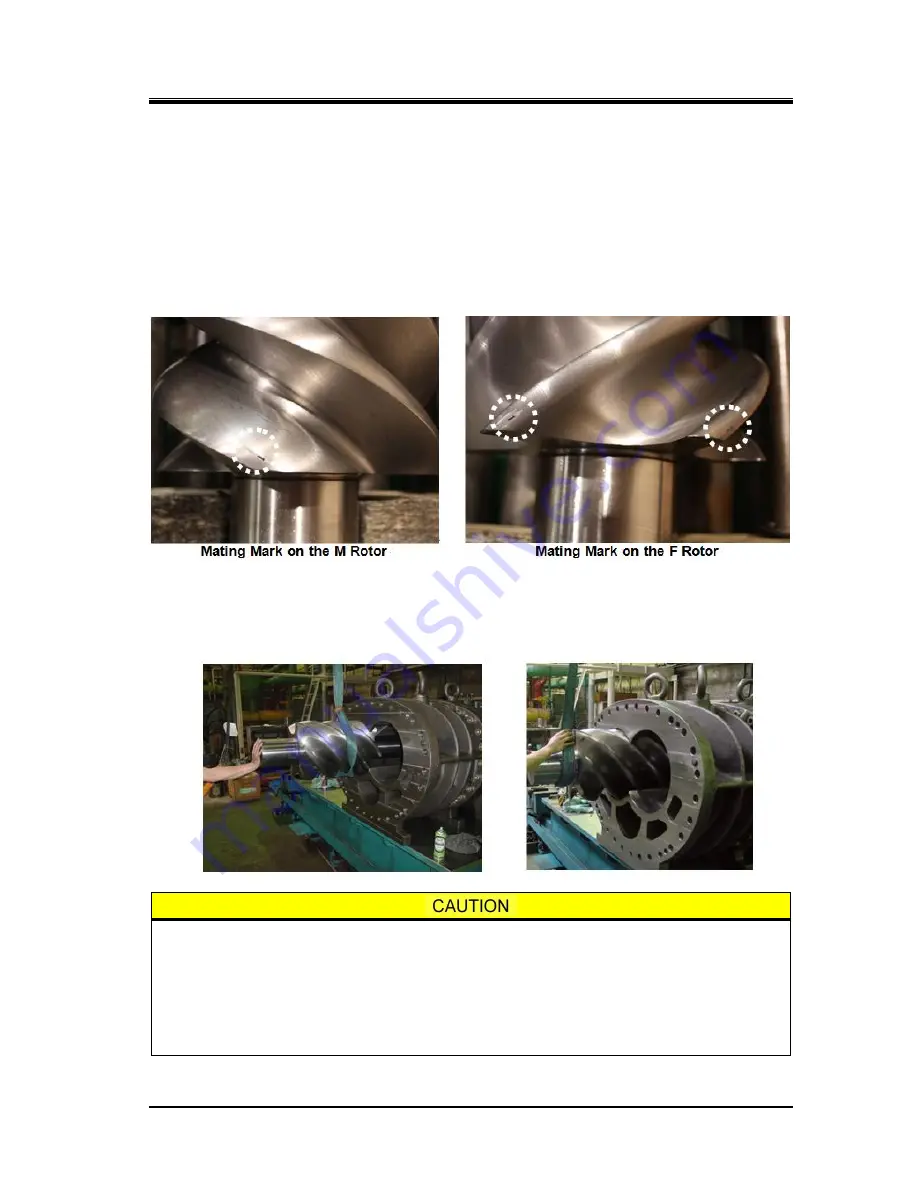

Both the M rotor and F rotor have a specific engagement position, and the position is marked by

carving.

In order to make it easier to match the positions when the rotors are installed into the main rotor casing,

a number is marked on the lobe tip: the M rotor has the marking on the discharge side, and the F rotor

has the marking on the suction side.

a) Apply sufficient amount of lubricating oil on the main bearing in the bearing head and on the

bearing area of the rotor shaft.

b) While it is easier to mate the markings if the F rotor is first installed into the casing, it is not a

mistake to install the M rotor first.

Regardless of which rotor is installed first, the tooth of the M rotor with the

carved marking of "1" must be set in between the F rotor

’s teeth that are marked

"1" and "2". As it affects smooth engagement of the teeth as well as the balance,

be sure to mate the markings as described above.

As the circumference of the rotor is touching the rotor casing in this condition, any

rotation of the rotor should be kept to the minimum required. Otherwise, the teeth tip

of the rotor may be worn.