Maintenance and Inspection

Warning

◆

When inspecting or maintaining this tool, be sure to turn off the power and unplug the power

cord.

1) Inspection the Bit

•

If a bit is worn or broken screw driving can be affected and the heads may be damaged.

The unique double-ended bits for Vislider allows both ends to be used. Turn over or replace the

bit with a new one as soon as possible.

2) Inspection of the Tool

•

As vibration through use can cause screws to loosen, periodically tighten screws as required.

Loose screws may cause an injury or accident.

3) Maintenance of the Motor

•

Dust in the motor should be discharged every 50 hours of operation. A method of discharging

the dust is to run the motor in a no-load situation and blow compressed air into the housing

through the front air vents causing the dust and air to exhaust together through the rear air

vents.

4) Inspection of Carbon Brushes

•

The carbon brushes should be removed and inspected periodically.

Woen the carbon brushes approach to the wear limit (6.5 mm), replace them with new ones

promptly.

The carbon brushes should be cleaned and checked to make sure they move smoothly in the

brush holder.

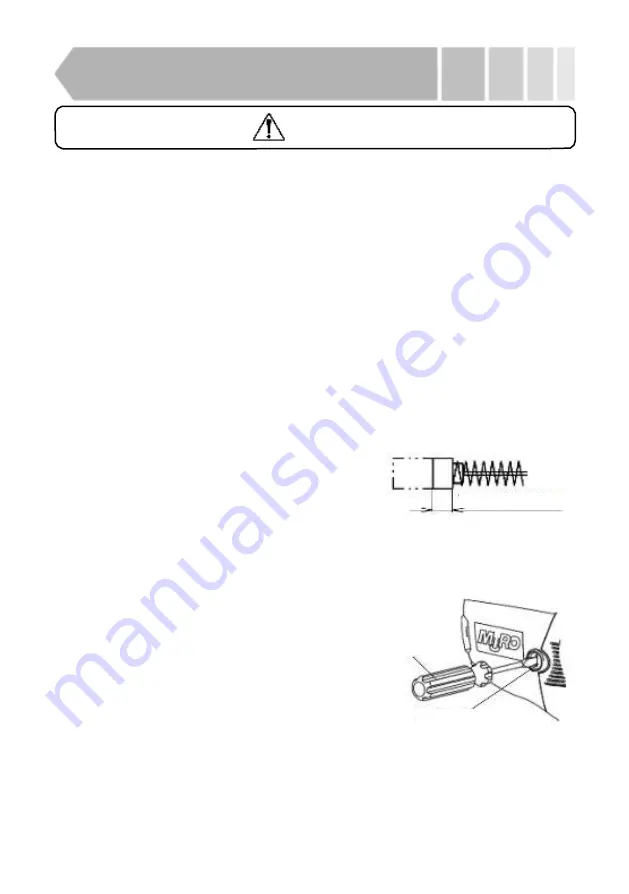

5) Replacement of Carbon Brushes

•

Remove the carbon cap with a slotted screw driver. Take out the worn carbon brushes and

insert new ones. Be sure to put the brush cap back after replacing the brushes.

Two carbon brushes make one set. Be sure to replace both of them at the same time.

6) Maintenance of Vislider

•

If dust gathers on the grip finger, guide cover, or guide pole, these parts may not slide smoothly.

Clean the parts thoroughly and apply two or three drops of a lubricant.

•

If the main unit becomes dirty, wipe it with a cloth and mild detergent. Do not use gasoline,

paint thinner, petroleum, and kerosene oils act to degrade plastics.

Wear limit:6.5 mm

Slotted

screw driver

Brush cap

Содержание VISLIDER VL42-FD

Страница 2: ......

Страница 18: ...THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 19: ...THIS PAGE INTENTIONALLY LEFT BLANK ...