MGS Installation and Operation Manual

22

1000-0085 Rev 0

Section 6. Functional Tests and Calibration

6.1. Introduction

To comply with the requirements of EN378 and the European F-GAS

regulation, sensors must be tested annually. However, local regulations may

specify the nature and frequency of this test.

CAUTION:

Check local regulations on calibration or testing

requirements.

CAUTION:

The MGS contains sensitive electronic components

that can be easily damaged. Do not touch nor disturb any of these

components

NOTE:

The MGS is calibrated at the factory. After installation, a

zero adjustment maybe required due to differences in

environmental conditions.

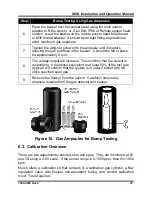

IMPORTANT:

If the MGS is exposed to a large leak it should be

tested to ensure correct functionality by electrically resetting the

zero setting and carrying out a bump test. See procedures below.

IMPORTANT:

Murco recommends annual checks and gas

calibration. Murco also recommends sensor replacement every 3

years or as required. Calibration frequency may be extended

based on application, but should never exceed 2 years.

IMPORTANT:

In applications where life safety is critical,

calibration should be done quarterly (every 3 months) or on a

more frequent basis. Murco is not responsible for setting safety

practices and policies. Safe work procedures including calibration

policies are best determined by company policy, industry

standards, and local codes.

Содержание MGS

Страница 10: ...MGS Installation and Operation Manual 10 1000 0085 Rev 0 Figure 2 EC or IR Sensor Components and Wiring ...

Страница 11: ...MGS Installation and Operation Manual 1000 0085 Rev 0 11 Figure 3 SC Sensor Components and Wiring ...

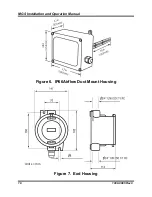

Страница 17: ...MGS Installation and Operation Manual 1000 0085 Rev 0 17 Figure 5 IP66 Housing with Splashguard ...