OP

6

Innovation. Quality. Performance. Best in Industry. Worldwide.

Using Rapid Shape

Once JobNameServer has been verified on the system and the plasma head has been calibrated, Rapid Shape can

be used in conjunction with the cutting sequence.

1. Make sure JobNameServer

is running on the computer.

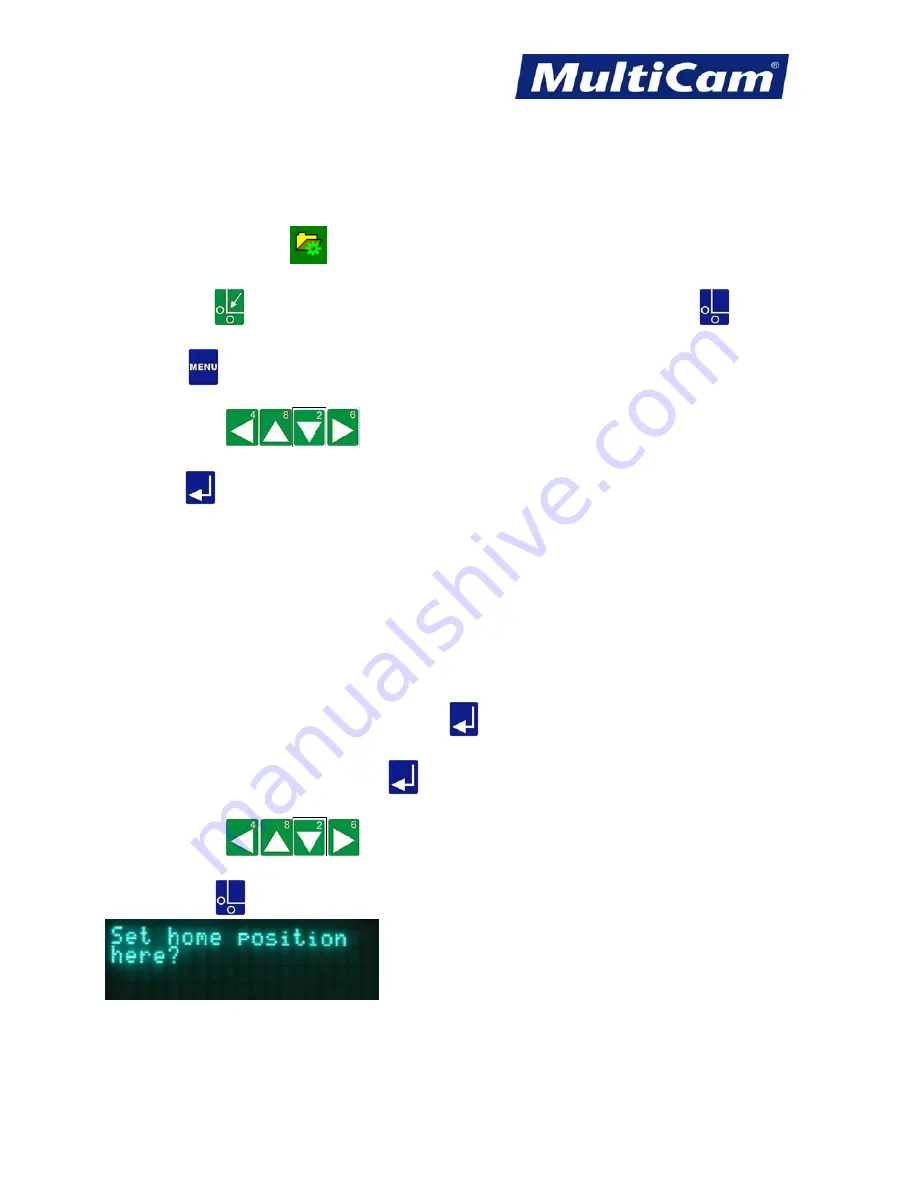

2. Press

Go Home

or move to a location where 0,0 will be located and press

Set Home

.

3. Press

Menu

to access the menu system.

4. Press

Jog Arrows

until Digitize is highlighted in blue.

5. Press

Enter

to access the Digitize sub-menu.

6. Set the 5 options for Rapid Shape: Scan Rate, Step Size, Scan Mode, Add Corners, and Output Start.

a.

Scan rate

sets the speed the system will auto scan. The default setting is 2.0” per second.

b.

Step Size

sets the distance along a line between 2 scanned points. The default setting is .15”.

c.

Scan Mode

sets the style of scanning to be completed. Operators should select EDGE for templates and

LINE for drawings or patterns.

d.

Add Corners

adjusts for corners when detected by the system.

e.

Output START

places “START” at the beginning of the G-Code file, which is required by some software

packages due to the importance of the G-Code file.

7. Move the cursor to “Start Digitize” and press

Enter

.

8. Enter a numeric file name and press

Enter

.

9. Press

Jog Arrows

to place the

center of the plasma head

over the front right corner

of the material.

10. Press

Set Home

.

Routers * Lasers * Plasma * Water Jets * Knife Cutters

www.MultiCam.com v. 03 13