Mueller E-Star OESE 7.5 and 9 HP HFC Condensing Unit

Installation and Operation Manual, Part No. 8828748

Effective June 16, 2020

11.2

MAINTENANCE PROCEDURES

The E-Star OESE condensing unit requires minimal maintenance. The following scheduled maintenance

procedures are recommended and should be performed by a knowledgeable service technician on an annual basis:

1. Clean the condenser tubes and fins from accumulated dust or other foreign matter to ensure proper air flow.

2. Check the refrigerant charge described in Section 3.3. If the charge is low, perform a leak test on the complete

system and repair.

3. Check for proper superheat, as described in Section 5.

4. Check for proper incoming supply voltage.

5. Measure the amperage draw of the compressor and verify that it is within 10% of the compressor’s technical

data chart.

6. Check all electrical connections, ensuring that they are clean and tight.

7. Check the compressor’s wrap-around crankcase heater for proper operation.

8. Check for proper operation of the low-, high-, and fan-pressure switches as described in Section 9.

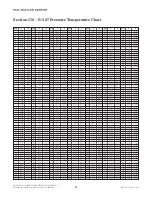

9. Complete a performance survey for each condensing unit verifying proper cooling capacity. Please refer to

Section

11.1.

11.3

SAFETY ALERT

• All maintenance and service must be performed by trained and knowledgeable service technicians.

• Individuals who are not trained and certified in proper refrigeration and electrical procedures should

not attempt servicing this equipment.

• This equipment starts automatically!

• All guards and covers must be in place during operation to prevent mechanical and electrical hazards!

23

!