Figure 4-24

Section

T51 • E51

Page 517

Dated

February 2014

P3 & P15 BEARING PEDESTAL

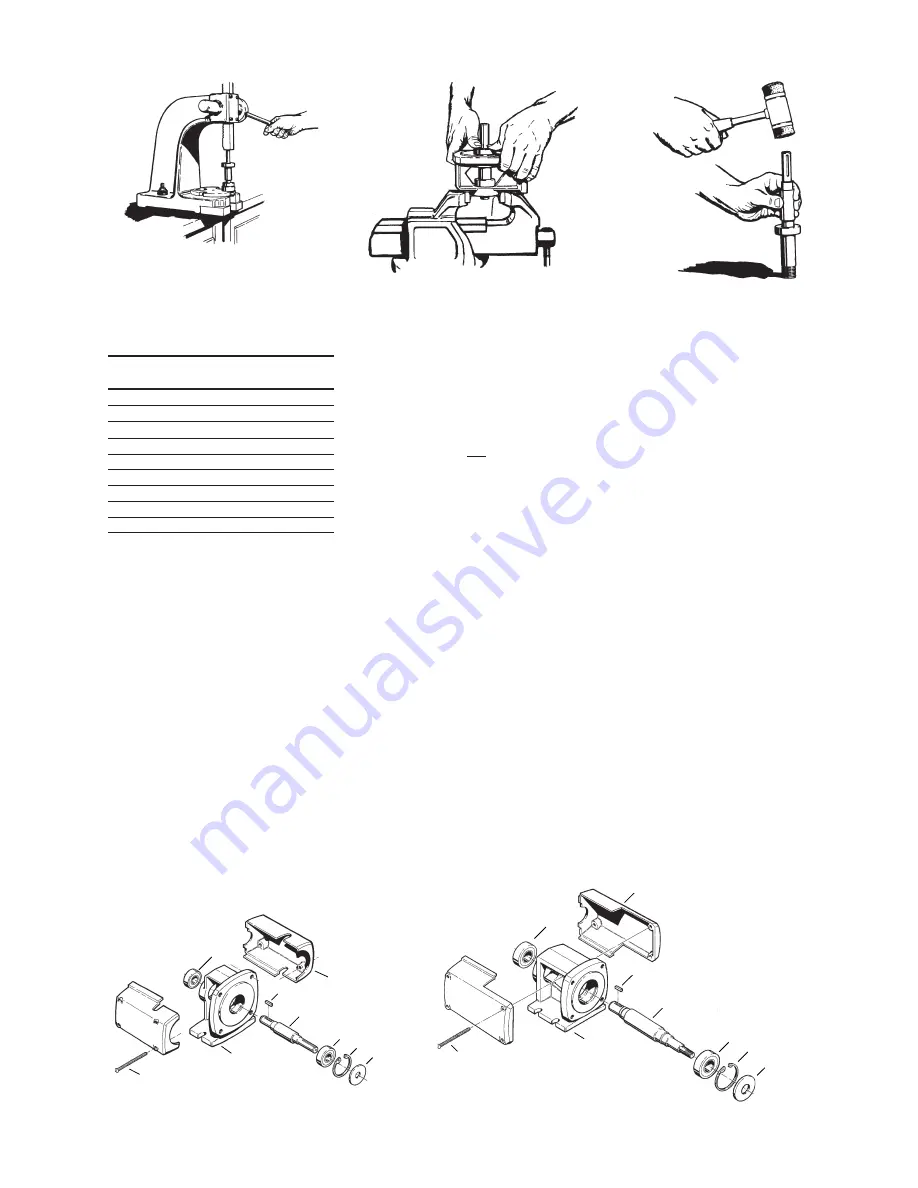

Figure 4-19

P3 Bearing Pedestal

Figure 4-20

P15 Bearing Pedestal

30

23

17

24

4

21

3

33

24A

30

23

17

24

4

33

24A

3

21

Figure 4-23

Figure 4-25

must seat against the shoulder for

proper alignment. Refer to Figure

4-23. *Also refer to Alternate

bearing installation procedures.

CHART 1

NAME/DESCRIPTION

PART

NO.

QTY.

Bearing Pedestal

3

1

Snap Ring/Bearing Retainer

4

1

Shaft

17

1

Flinger

21

1

Key Coupling

23

1

Ball Bearing/Inboard

24

1

Ball Bearing/Outboard

24A

1

Coupling Guard/Halves

30

2

Capscrew

33

4

2. Place the pedestal, pump mount-

ing surface up, in a vise or suitable

fixture and insert the bearing

assembly. It should be possible to

install the shaft assembly with firm

thumb pressure. Refer to Figure

4-24. If more force is required, the

butt end of a hammer handle or

plastic mallet may be helpful. The

shaft assembly should never be

forced or driven in.

3. Install the snap ring (#4) in the

pump end of the pedestal. Be

sure the snap ring is seated prop-

erly in the groove. The beveled

edge of the ring should face away

from the bearing.

4. Install the flinger over the snap

ring. The bearing pedestal is now

ready for pump and motor instal-

lation.

*Alternate bearing installation

procedures.

If an arbor press is not available,

the bearings may be installed on the

shaft using the following procedure:

This procedure is not recommended

and should only be used in an emer-

gency situation.

1. Stand a piece of 3/4” pipe for P3

or a 1-1/4” piece of pipe for P15,

with the threads cut off, on a work-

bench or similar flat surface, with

the bearing placed on the correct

shaft end.

2. Insert the shaft into the pipe so the

bearing is between the pipe and

the shoulder of the shaft. Refer to

Figure 4-25.

3. Using extreme caution, gently tap

on the end of the shaft until the

bearing rests against the shoulder.

Never attempt to install the bear-

ings by striking the outer race.

4. Repeat step 3 for the other bear-

ing.

4E Testing and Final Adjustments

1. Check to be sure that the rotating

assembly turns freely. Turn the

shaft by hand. If it is tight or rough

spots are encountered, it is likely

that at least one of the bearings

was damaged during disassembly/

assembly operations and will have

to be replaced.

2. Look to make sure that the lip

seals on the bearings are posi-

tioned properly in their grooves.

Correct if necessary. As the

bearings are turned, the grooves

should appear wet with oil but

have no visible grease present.

3. Recheck the snap ring on the

large bearing end. It should be

firmly in place, and no axial motion

should result from gentle tapping

on either end of the shaft. (Use a

soft mallet so shaft surfaces are

not damaged.)

4. No adjustments are possible or

required. Proceed with the ap-

propriate pump end assembly

operations. Refer to Section 4

SERVICE - PUMP ENDS (Final

testing is done after the pump end

is in place.)