Section

E41•T41

Page 514

Dated

June 2016

97-4622-01-588

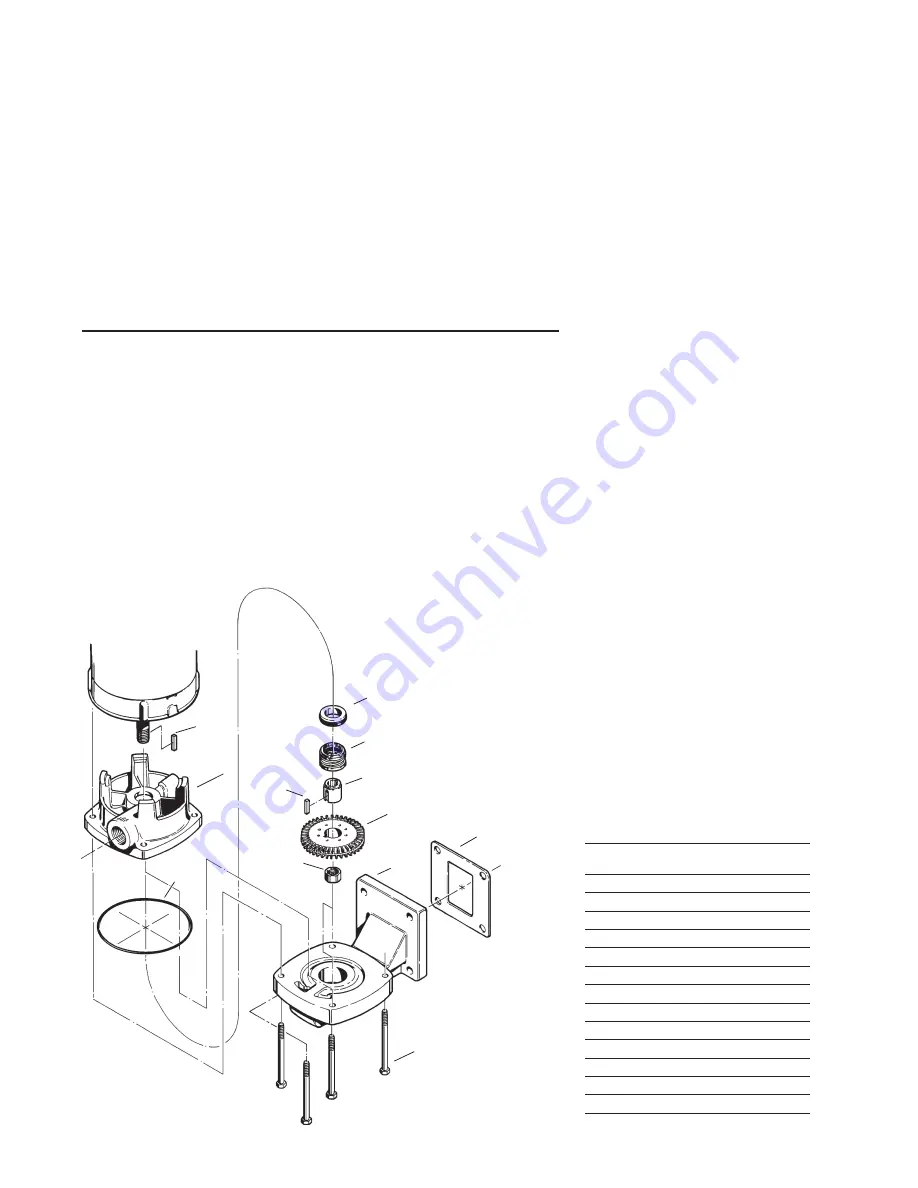

C15 VERTICAL

FLANGE MOUNT PUMP

Figure 4-20

125

12

14

11

15

23

60

19

2

7

1

23A

C15

4.

Service

E41•T41 SERIES

T41 BEARING PEDESTALS

A.

Preliminary

B.

Disassembly

C.

Inspection of Components

D.

Reassembly

E.

Testing and Final Adjustments

4A Preliminary (P3 and P15)

1. Disconnect the inlet and outlet

piping before unbolting the pump.

If the pipes are corroded, use pen-

etrating oil on the threads to aid in

removal.

2. Unbolt the pump from the base

and remove. Disassembly instruc-

tions for the pump are found in

section 4, T41 PUMP ENDS. All

work on the unit should be per-

formed on an elevated work-bench

whenever possible.

The disassembly and reassembly

procedures are broken into two sec-

tions covering the following units:

4B — Disassembly of the P3 and

P15 Bearing Pedestals

4D — Reassembly of the P3 and

P15 Bearing Pedestals

Exploded views of each unit, Figures

4-24 and 4-25 are provided for refer-

encing the numbers in the following

procedures, i.e. flinger (#21).

4B Disassembly (P3 and P15)

The following tools and equipment

are needed for disassembly of the P3

and P15 units:

1. Soft plastic or wooden mallet.

2. Arbor press or vise.

3. 3/4” X 6” piece of water pipe for

P3, 1-1/4” X 6” for P15.

4. Internal snap ring plier.

5. Penetrating oil.

When installing or removing bearings

from the shaft, the use of an arbor

press is strongly recommended.

To disassemble the pedestal:

Refer to Figures 4-19 and 4-20 for

reference to the numbered parts in

the procedures below.

NAME/DESCRIPTION

PART

NO.

QTY.

Motor Bracket

1

1

Cover/Vertical

2

1

“O” Ring/Casing

7

1

Impeller

11

1

Seal Rotating Element

12

1

Seal Stationary Seat

125

1

Drive Sleeve/Impeller Driver

14

1

Impeller Nut

15

1

ThruBolt

19

4

Nut

20

2

Key/Impeller Drive

23

1

Key/Sleeve Drive

23A

1

Gasket

60

1

4I Testing and Final Adjustment

The pump is now ready for

installation.

Final adjustments will be made with

the pump in operation.

1. Reconnect the electrical

connections referring to the

colored or numbered tape used to

mark the wires.

2. Connect all piping and fill the

pump with fluid .

3. Make sure all valves are open,

and fluid will flow through the

system.

4. Start the pump.

5. Check for leaks on pump and

piping. Special attention should

be given to the seal area at the

rear opening in the motor bracket.

6. Under pressure, the impeller will

find its “hydraulic” balance.

7. Using an amprobe or similar

device, check for motor overload.

8. While the impeller is finding its

balanced position, it is common

to experience some variance in

readings. After a run-in period the

readings should level off.

This completes the adjustment and

testing phase. The pump is ready for

service.