EN

21

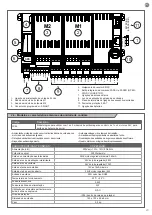

4 - PRODUCT INSTALLATION

4.1 - Installation

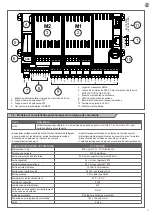

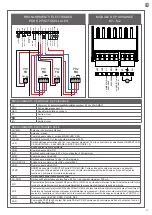

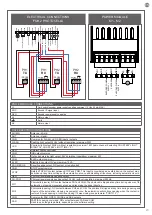

4.2 - Electrical connections

4.3 - Emergency unblocking

Insert the ball E into the special hole after having greased it. Insert

the control rod A over the foundation box sup-porting pivot B. Fix

with a strong welding the wing of the gate on the release lever C,

then put everything on the driving bracket A. Grease the mechanism

using the appropriate grease nipple D (Fig.4a).

Installing the gear motor.

Place the motor reducer gear unit inside the foundation box.

Fix the motor reducer in place inside the foundation box by tightening

the 4 nuts (Fig.5).

Assemble the lever engine (1) on the motor shaft and tighten the screw (2).

Connect the lever engine (1) command to the bracket (3) through

the lever (4) (Fig.5a).

Connect the motor to the control panel following the instructions in

the manual installation of the card.

Installation of the limit switches in closing

Move the gate in a position fully closed, then adjust and fasten the

screw (Fig. 6).

Installation of the limit switches in opening

Place the gate in the maximum open position, and then then adjust

and fasten the screw (Fig. 6a)

In the case of a power failure, the gate can be unblocked

mechanically by operating the motor.

Insert the supplied unlocking key and rotate completely the handle

(above 90°) (Fig. 8).

To lock back follow the reverse procedure.

FLASH24 24V

COLOR CABLE

RIGHT

LEFT

Blue

Opening

Closing

Brown

Closing

Opening

They shall state that the installer shall check that the temperature

range marked on the drive is suitable for the location.

Ensure that the concrete used is prop-erly cured prior to

proceeding with the following steps.

To operate the engine 230V is essential to connect the capacitor

between black and brown of the motor.

Always connect the earth cable to the mains power earth

system with a cable minimum cross sectional area of 1.5 mm

2

Your gate shall be equipped with central and side stops, which

are fundamental for the good system operation. (Fig 7).

The automation system must be equipped with a pressure-

sensitive edge protecting all possible crushing points (hands,

feet, etc.) in accordance with the requirements of the EN 13241-

1 standard.

WARNING!

WARNING!

WARNING!

WARNING!

WARNING!

WARNING!

Before starting the installation, make sure that the product is intact

and that the packaging contains all the components shown.

Make sure that the mounting area is compatible with the overall

dimensions (Fig.1).

Check the allowed use limitation in the diagram in Fig.2

Fig.3 is an example of a typical system:

- Operators (1)

- Photocells (2)

- Posts for photocells (3)

- Flashing light with integrated aerial (4)

- Key or digital switch (5)

Positioning the foundation box and the lever control and blocking

system

Depending on the dimensions, dig a suitably sized foundation ditch

(it is recommended to provide adequate drainage in order to avoid

water pooling).

Place the foundation box inside the trench, with the support pivot

aligned with the hinge axis.

Install a conduit for the electrical cables, and another for drainage.

Embed the foundation box in concrete, ensuring it is level and plumb

(Fig.4)

Содержание FLASH24

Страница 39: ...39 IMAGES Fig 1 FR Attention EN Attention PT Aten o...

Страница 40: ...40 Fig 2 FR D verrouillage d urgence EN Emergency unblocking PT Desbloqueio de emerg ncia 1 2 3...

Страница 41: ...INSTALLER DATA INSTALLER DATA DATE SIGNATURE...

Страница 42: ...42 NOTE...

Страница 43: ...43...