© Motor City Wash Works, Inc. 48285 Frank, Wixom Michigan 48393 U.S.A.

Phone: 248.313.0272 ▪ Fax: 248. 313.0271

8MANULHYDDOC0004 REV 1.0

www.motorcitywashworks.com

9

3. Ambient Heat

Exposure to high external ambient temperatures

can dramatically shorten hose life.

Always route hose assemblies away from heat

sources or install a protective sleeve or baffle

plate

.

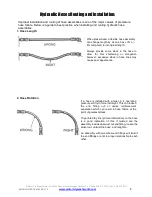

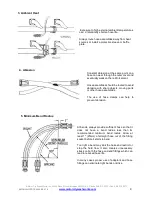

4. Abrasion

Constant abrasion at the same point on a

hose can wear through the outer cover and

eventually weaken the reinforcement.

Hose assemblies should be routed to avoid

abrasion with sharp objects, moving parts

or other hose assemblies.

The use of hose clamps can help to

prevent abrasion.

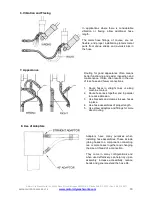

5. Minimum Bend Radius

At bends, always provide sufficient hose so that it

does not have a bend radius less than its

recommended minimum bend radius. Allow at

least 1" (25mm) of straight hose out of the fitting

socket before it starts to bend.

Too tight a bend may kink the hose and restrict or

stop the fluid flow. It also creates unnecessary

stress on both the hose and end fittings which can

lead to reduced hose life.

In many cases proper use of adaptors and hose

fittings can eliminate tight bends or kinks.