© Motor City Wash Works, Inc. 48285 Frank, Wixom Michigan 48393 U.S.A.

Phone: 248.313.0272 ▪ Fax: 248. 313.0271

8MANULHYDDOC0004 REV 1.0

www.motorcitywashworks.com

4

Notes and safety Symbols

Where necessary, important points will be highlighted in this manual, using the following symbols:

NOTES:

PROVIDES FURTHER INFORMATION!

WARNING!

DANGEROUS SITUATION WHICH MAY CAUSE

EQUIPMENT DAMAGES, PERSONAL INJURIES OR FATALITIES!

Always follow all “Notes”, “Warning” and instructions. Not doing so may have serious

consequences on the overall performance of the washing equipment and/or the safety of

the people working on the equipment!

Installation Instruction for EQUIPMENT POWER PACK [10 – 15HP MOTOR]

1.

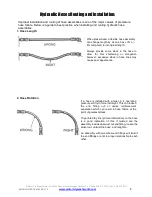

Placing power pack in back room is at the discretion of available real-estate. There is no hard and fast rule of

positioning the tank. Keep in mind for the electrician to connect motor wiring before tank is filled with oil so they

can move as needed prior to anchoring to the floor with ¼” lag bolts. Use foot pads if desired. [not provided by

MCWW]

2.

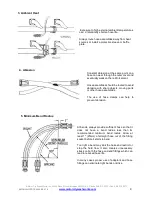

Hydraulic hose requires ½” JIC female swivel fittings for feed and return lines.

3.

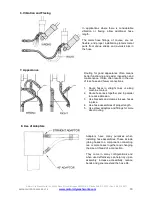

Input wiring for float bobber is determined by your car wash controller input. Contact car wash controller

manufacturer for details.

STOP!

PRECAUTION TO TAKE TO AVOID EQUIPMENT

MALFUNCTION OR ERROR!