© Motor City Wash Works, Inc. 48285 Frank, Wixom Michigan 48393 U.S.A.

Phone: 248.313.0272 ▪ Fax: 248. 313.0271

8MANULHYDDOC0004 REV 1.0

www.motorcitywashworks.com

6

2.

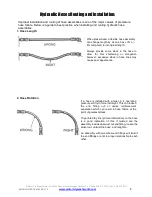

Sight Gauge:

Ability to view oil level in tank and it a thermometer for temperature.

3.

Hydraulic outlet:

Feed line to hydraulic motor

4.

Hydraulic return line:

Hydraulic line connection from hydraulic motor.

5.

Speed adjustment knob:

Changes fluid volume to slow [turn knob clockwise] or speed up

[turn knob counter clockwise] the hydraulic motor.

6.

Jam nut:

Tightening [clockwise] secures valve thread from vibration changing speed

unknowingly. There is also a jam nut on the pressure gauge valve thread, same concept.

7.

Pump priming filler cap:

Removing cap allows you to fill hydraulic oil inside to prime pump.

Replace cap as soon as your done filling oil and tighten snug.

8.

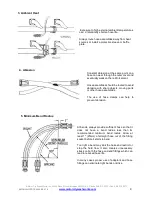

Pressure valve:

Changes pressure of the pumps output, recommended 900 PSI

ONLY

viewable on gauge when hydraulic outlet is plugged [deadhead] and pump is on with gauge

valve open. When not adjusting keep jam nut tight on valve thread. This will prevent

vibration from changing pressure unknowingly.

9.

PSI Gauge:

Allows the ability to see what the pump pressure is at when in use. To help

prolong the operation of the gauge you can have gauge valve closet to stop oil from entering

gauge. Open when needing to view PSI pressure on gauge.

10.

Gauge valve:

Loosen jam nut for opening gauge valve [counter clockwise] allows oil in gauge.

Close valve [clockwise] and tighten jam nut for normal use. (Gauge needle will not move)

11.

Filler cap:

Removing cap reveals opening for filling Hydraulic fluid into the tank. [ISO 32

viscosity recommended]

12.

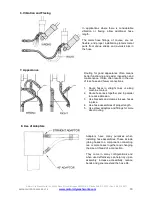

Filter:

This is for the return oil for filtration. Change every 3000 miles or 1500 hours

whichever comes first. *Lubricate gasket of new filter before installation.

13.

Filter gauge:

needle in green filter is good. Needle in red filter over due to be changed.

14.

By-pass tee:

Oil not needed will be dumped back to the tank Via this hose connected to the

by-pass tee.

15.

Clean out cover:

Opening will allow you access to left over oil at bottom of tank for cleaning.