SECTION 3:

SETTING UP

3.1.

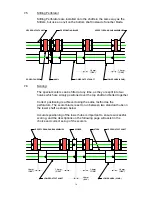

In setting the machine for a job, it is advisable to start by positioning the side

lay to a suitable position (see below).

This is achieved by unscrewing the knobs (B).

3.2

Lift the knobs out of their holes, and at the same time, move the side lay

assembly to the desired position. Re-tighten screws, ensuring that the side lay

is parallel to the side of the machine.

The side lay is normally set so that the paper is running approximately along

the centre of the machine.

The machine is supplied with a mixture of steel and glass balls:

Lightweight paper stocks may require the steel balls to be removed to

minimise creasing.

Heavy stocks, and when running a job landscape (i.e. long edge leading) may

require the glass balls to be replaced by steel balls to give increased drive on

the paper.

The side lay may be tilted, for folding out of square, by adjusting knobs (A). By

turning knobs (A) equally, the side lay may be used for obtaining final

sideways setting for perforating, etc. Position one sheet smoother at the free

edge of the sheet and the others as required.

3.3

With the side lay now set in position, move the operator side manifold by

loosening knobs (C) and (D).

4

(B)

(A)