Not feeding efficiently

Size control at wrong setting (see page 11).

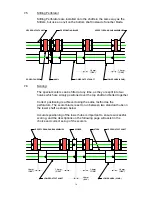

Paper gate in wrong Position (see page 7).

Slot in vacuum drum in wrong position (see

page 6).

Manifold set incorrectly (see page 5).

Manifold settings incorrect (see page 5).

Sheets creasing

Side lay balls too heavy.

Side lay tilted too far.

Motor speeds set incorrectly.

Roller pressures too tight.

Heavy stock sticks

Lower rail of top fold plate too far forward

in top fold plate

(see page 18).

Insufficient drive from top roller – decrease

caliper setting for top roller.

Letter fold or

Lower rail of second fold plate too far

zigzag fold jams

forward (see page 18).

in second fold

Bottom roller set too tight on second fold –

plate

increase caliper settings from 3 to 4 or 5.

Inside edge of letter

Inside fold too tight to second fold –

fold turning back

adjust fold lengths.

Fold length varying

Original stock varying in length.

Original stock having different grain direction.

Motor speeds not set to same settings.

Dirt build up on rollers.

Roller caliper settings incorrect.

Fold plate deflector not locked.

False fold on

Insert extra thicknesses to bottom caliper.

gate fold

27