37

CHAPTER 3

●

General Technical Considerations

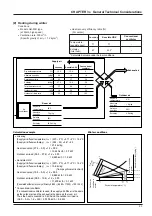

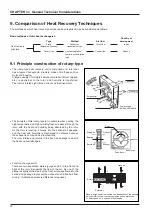

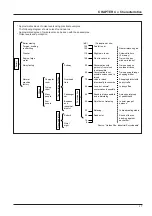

9.2 Comparison of static-type and rotary-type heat recovery units

Item

Construction/

principle

Moving parts

Material quality

Mounting of prefilter

Element clogging

Air leakage

Gas transmission

rate

Bacteria

transmission rate

Operation during

off-seasons

Maintenance

Life

Model system and

comparison

Standard treatment

air volume

Enthalpy recovery

efficiency

Pressure loss

Installation space

(W

×

D

×

H)(mm)

Static-type

<Conductive transmission-type: cross-flow>

Static-type transmission total heat recovery unit

with orthogonally layered honeycomb shaped

treated paper formed into multiple layers.

●

As the supply air and exhaust air pass through

different passages (sequentially layered), the air

passages are completely separated.

●

None

Fixed core

Treated paper

Required (periodic cleaning required)

●

Occurs (state where dirt adheres onto element air

passage surface. However, this is easily removed

with a vacuum cleaner.)

Approximately 2.5% air leak at standard fan

position.

Leaks on the air supply side can be reduced to 0 by

leaking the loss air volume (approx. 10%) on the

exhaust side with the fan position to the core.

●

Gas transmission ( Ammonia

: 28%,

hydrogen sulfide : approx. 6.7%)

●

Low (As air intake/exhaust are separate,

transmission is low.)

Bypass circuit required (SA pass or RA pass only)

Core cleaning: More than once (every two years)

The core surface will clog with lint and dirt, but

cleaning is easy with a vacuum cleaner.

Only the two core air passage intakes need to be

cleaned.

Core: Semi-permanent (10 years or more)

(The static-type does not break.)

o

Available from small to large.

Example

o

Characteristic design of small

LU-1605

and medium models possible.

Large models are easy to

match to machine room layout.

40 to 25,000 m

3

/h

8,000 m

3

/h

Temperature:77%

Enthalpy

Heating : 71%

Cooling : 66%

170 Pa

Effective for small to medium capacity

600

×

2100

×

2540

(Layout is free according to combination.)

Rotary-type

<Heat accumulation/humidity accumulation-

type: counterflow>

The rotor core is composed of honeycomb-shaped

kraft paper, etc., to which a moisture absorbent is

applied (lithium chloride, etc.). This rotor is rotated,

and heat accumulation/humidity accumulation -

heat discharge/humidity discharge of total heat

exchange is performed by passing the exhaust and

intake airs into a honeycomb passage.

×

Supply air and exhaust airs flow into the same air

passage because of the rotary-type construction.

×

Used (rotor driven with belt by gear motor)

Rotor core (8rpm)

Treated paper, aluminum plates, etc.

Required (periodic cleaning required)

×

Occurs (Dust is smeared into element air passage filter.)

(The dust adhered onto the core surface is smeared

into the air passage by the purge sector packing.

Thus, it cannot be removed easily and the air

volume decreases.)

×

Purged air volume occurs

To prevent leakage of exhaust to the air intake side, a

purge air volume (6 to 14%) leak is created to the

exhaust side. Thus, there are problems in the purge

sector operation conditions (pressure difference,

speed), and the air volume balance must be balanced.

×

Gas transmission (Ammonia

: 45-57%,

hydrogen sulfide : approx. 3.2-4%)

×

High (As air intake/exhaust are the same,

transmission is high.)

Bypass circuit required (Required on both air intake

and exhaust air outlet sides)

(In theory, operation is possible by stopping the

rotation, but the core will over-absorb, causing rainage.)

Core cleaning: Once every one or two years

Cleaning is difficult as dust is smeared into core

with the packing.

×

Gear motor for rotor drive

: Periodic inspection

×

Rotor bearing, rotor drive belt : Periodic inspection

Core: Semi-permanent (10 years or more)

(Periodic replacement is required according to the

rotor bearings and core clogging.)

×

Rotor drive belt

: Periodic replacement

×

Drive motor, rotor bearing : Periodic replacement

Large type only

Example

×

Small models are difficult to

EV-1500

design because of the rotor

magnitude.

o

100 to 63,000 m

3

/h

8,000 m

3

/h

74%

180 Pa

Large capacity models are

320

×

1700

×

1700

effective

Measure of useability

●

High

o

Average

×

Poor

Содержание Lossnay PZ-41SLB-E

Страница 4: ...CHAPTER 1 Ventilation for Healthy Living Lossnay Unit ...

Страница 17: ......

Страница 18: ...CHAPTER 2 Lossnay Construction and Principle ...

Страница 24: ...CHAPTER 3 General Technical Considerations ...

Страница 41: ......

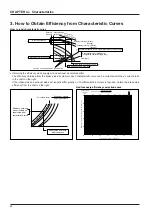

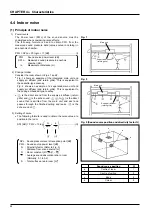

Страница 42: ...CHAPTER 4 Characteristics ...

Страница 56: ...53 CHAPTER 4 Characteristics ...

Страница 57: ...54 CHAPTER 4 Characteristics ...

Страница 59: ......

Страница 60: ...CHAPTER 5 System Design Recommendations ...

Страница 68: ...CHAPTER 6 Examples of Lossnay Applications ...

Страница 83: ......

Страница 84: ...CHAPTER 7 Installation Considerations ...

Страница 88: ...CHAPTER 8 Filtering for Freshness ...

Страница 96: ...CHAPTER 9 Service Life and Maintenance ...

Страница 98: ...CHAPTER 10 Ventilation Standards in Each Country ...

Страница 101: ......

Страница 102: ...CHAPTER 11 Lossnay Q and A ...

Страница 108: ...Lossnay Remote Controller ...

Страница 109: ......

Страница 197: ...MEMO ...

Страница 198: ...Y04 002 Jul 2004 MEE ...