OM-239026 Page 20

SECTION 6 – OPERATION

6-1.

Controls

OM-239026 Page 17

SECTION 6 OPERATION

6-1.

Controls

!

Only use the fume extractor to ex-

tract weld fumes. Do not use the

fume extractor to extract hot gases

(above 140

°

F/60

°

C), wood or ce-

ment dust, engine exhaust, liquid

vapors,

explosive

materials,

aggressive fumes (acid), fumes

from burning objects, or fumes from

cleaning, cutting, gouging, grind-

ing, painting, flame spraying, sand

blasting, or other non-welding op-

erations.

!

Do not position the fume extractor

hood in any location that will allow

the weld fumes to be pulled into the

operator’s breathing zone.

!

Minimize cross drafts that affect

fume extraction by closing doors/

windows and/or installing weld

screens/curtains.

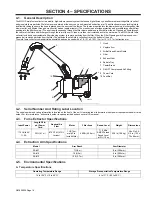

1

Power Switch

Use switch to turn unit On and Off.

2

Filter Gauge

Gauge only indicates air pressure drop

across the filter. Clean or replace filter

when reading is over 4 in. w.c. (10 x 100 Pa)

or whenever air flow is too low to extract

fumes. The gauge should read between 0.1

and 0.5 in. w.c. (0.25 and 1.25 x 100 Pa) at

start-up (with a clean filter).

3

Filter Cleaning Switch

Use switch to operate filter cleaning sys-

tem. Clean or replace filter when reading is

over 4 in. w.c. (10 x 100 Pa) or whenever

air flow is too low to extract fumes. (See

Sections 7-3 and 7-4 for filter maintenance

information).

4

Particle Tray Release Lever

Use lever to release tray after cleaning filter

(Section 7-3).

5

Hood

Position the hood to minimize the effects of

cross drafts from outside air sources or

from other operations. Tilt the hood at a 45

°

angle and position it as close to the welding

arc as possible but no further than 14 in. (36

cm) from the arc.

6

Damper Control

The damper allows the user to regulate air

flow. In most cases, open damper fully (as

shown).

245608 / 228000-E

5

6

1

2

4

3

245608 / 228000-E

Only use the fume extractor to ex-

tract weld fumes. Do not use the

fume extractor to extract hot gases

(above 140° F/60° C), wood or ce-

ment dust, engine exhaust, liquid

vapors, explosive materials, ag-

gressive fumes (acid), fumes from

burning objects, or fumes from

cleaning, cutting, gouging, grind-

ing, painting, flame spraying, sand

blasting,

or

other

non-welding

operations.

Do not position the fume extractor

hood in any location that will allow

the weld fumes to be pulled into

the operator’s breathing zone.

Minimize cross drafts that affect

fume extraction by closing doors/

windows and/or installing weld

screens/curtains.

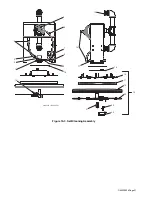

1

Power Switch

Use switch to turn unit On and Off

2

Filter Gauge

Gauge only indicates air pressure drop

across the filter. Replace filter when reading

is over 4 in. w.c. (10 x 100 Pa) or whenever

air flow is too low to extract fumes. The

gauge should read between 0.1 and 0.5 in.

w. c. (0.25 and 1.25 x 100 Pa) at start-up

(with a clean filter).

3

Filter Cleaning Switch

Use switch to operate filter cleaning system.

Clean or replace filter when reading is over 4

in. w.c. (10 x 100 Pa) or whenever air flow is

too low to extract fumes. (See Sections 7-3

and 7-4 for filter maintenance information).

4

Particle Tray Release Lever

Use lever to release tray after cleaning filter

(Section 7-3).

5

Hood

Position the hood to minimize the effects of

cross drafts from outside air sources or from

other operations. Tilt the hood at a 45° angle

and position it as close to the welding arc as

possible but no further than 14 in. (36 cm)

from the arc.

6

Damper Control

The damper allows the user to regulate air

flow. In most cases, open damper fully (as

shown)

Содержание FILTAIR

Страница 4: ......

Страница 18: ......

Страница 37: ...Notes Visit www youtube com MillerWelders for informational videos ...

Страница 39: ......