OM-239026 Page 24

7-3.

Cleaning Filter

OM-239026 Page 21

7-3.

Cleaning Filter

245608 / 245613

!

Close cover before starting unit or

operating filter cleaning system.

!

Do not operate unit without filter or

with dirty (plugged) filter.

!

Clean or replace filter when dirty.

!

Allow cooling period before in-

specting or replacing filter, or clean-

ing particle tray and spark guard.

!

Do not breathe the particles col-

lected by the fume extractor. Wear

approved safety equipment (respi-

rator, gloves, long sleeve shirt)

when servicing filter and spark

guard. Dispose of used element and

collected particles according to lo-

cal, state, and federal requirements.

!

If ANY air is injected into the skin or

body seek medical help immedi-

ately.

!

Read and understand the Material

Safety Data Sheets (S DSs ) and

the manufacturer’s instructions for

metals, consumables, coatings,

cleaners, and degreasers.

See Section 5-5 for compressed air re-

quirements for proper filter cleaning.

!

Wear protective equipment when

disconnecting compressed air sup-

ply. Internal air tank is under pres-

sure and will discharge when air

supply is disconnected.

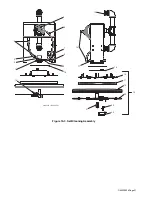

1

Filter Cleaning Switch

Use switch to operate filter cleaning sys-

tem. Clean or replace filter when Filter

gauge reading is over 4 in. w.c. (10 x 100

Pa) or whenever air flow is too low to ex-

tract fumes. Keep cover closed during

cleaning to maintain a tight seal around fil-

ter.

To clean filter, press and release Filter

Cleaning switch. The filter cleaning system

operates only when the unit is off.

The filter cleaning system begins oper-

ation when the internal fan completely

stops.

Close damper before operating filter

cleaning system.

The system cleans the filter in about 15

seconds. Wait until the cleaning has

stopped before removing particles from

tray.

2

Particle Tray Release Lever

3

Particle Tray

Push lever down to release particle tray.

Pull out tray. Remove particles from tray

after every cleaning cycle. Reinstall tray

and pull lever up to secure tray in position.

Inspect filter after cleaning (Section 7-4).

Start unit and check Filter gauge reading.

!

Replace filter if, after cleaning, Filter

gauge reading is over 4 in. w.c. (10

x 100 Pa) or air flow is too low to ex-

tract fumes.

Tools Needed:

3

1

2

OM-222 Page 1

NGO’s

tools/

helmet

weldshield

faceshield

glasses

hairdryer

cclamp

rpmmeter

benchvise

popriveter

oilcan

filtersocket

hacksaw

belttensiongauge

sealant_1

snapringpliers

linepliers

pencil

fusepuller

mallet

scissors

tape

rubbergloves

weldgloves

earmuffs

electrodewrench

pinextractor2

tip_dress

sealant_2

pump pliers

T_allen

pinextractor (141761)

SOAP

bar soap

Liquid soap

Paper Clip

Needle-Nose Vise Grip

Ground Strap

Thermal Compound

Trowel

Chisel

Torx

ear plugs

OM-222 Page 1

NGO’s

tools/

helmet

weldshield

faceshield

glasses

hairdryer

cclamp

rpmmeter

benchvise

popriveter

oilcan

filtersocket

hacksaw

belttensiongauge

sealant_1

snapringpliers

linepliers

pencil

fusepuller

mallet

scissors

tape

rubbergloves

weldgloves

earmuffs

electrodewrench

pinextractor2

tip_dress

sealant_2

pump pliers

T_allen

pinextractor (141761)

SOAP

bar soap

Liquid soap

Paper Clip

Needle-Nose Vise Grip

Ground Strap

Thermal Compound

Trowel

Chisel

Torx

ear plugs

Close cover before starting unit or

operating filter cleaning system.

Do not operate unit without filter or

with dirty (plugged) filter.

Clean or replace filter when dirty.

Allow cooling period before in-

specting or replacing filter, or

cleaning particle tray and spark

guard.

Do not breathe the particles col-

lected by the fume extractor. Wear

approved safety equipment (respi-

rator, gloves, long sleeve shirt)

when servicing filter and spark

guard. Dispose of used element

and collected particles according

to

local,

state,

and

federal

requirements.

If ANY air is injected into the skin

or

body

seek

medical

help

immediately.

Read and understand the Safety

Data Sheets (SDSs) and the manu-

facturer’s instructions for metals,

consumables, coatings, cleaners,

and degreasers.

�

See Section

for compressed air re-

quirements for proper filter cleaning.

Wear protective equipment when

disconnecting

compressed

air

supply. Internal air tank is under

pressure and will discharge when

air supply is disconnected.

1

Filter Cleaning Switch

Use switch to operate filter cleaning system.

Clean or replace filter when Filter gauge

reading is over 4 in. w. c. (10 x 100 Pa) or

whenever air flow is too low to extract fumes.

Keep cover closed during cleaning to main-

tain a tight seal around filter.

To clean filter, press and release Filter

Cleaning switch. The filter cleaning system

operates only when the unit is off.

�

The filter cleaning system begins oper-

ation when the internal fan completely

stops.

�

Close damper before operating filter

cleaning system.

The system cleans the filter in about 15 sec-

onds. Wait until the cleaning has stopped be-

fore removing particles from tray.

2

Particle Tray Release Lever

3

Particle Tray

Push lever down to release particle tray. Pull

out tray. Remove particles from tray after

every cleaning cycle. Reinstall tray and pull

lever up to secure tray in position.

Inspect filter after cleaning (Section 7-4).

Start unit and check Filter gauge reading.

Replace filter if, after cleaning, Fil-

ter gauge reading is over 4 in. w.c.

(10 x 100 Pa) or air flow is too low

to extract fumes.

Содержание FILTAIR

Страница 4: ......

Страница 18: ......

Страница 37: ...Notes Visit www youtube com MillerWelders for informational videos ...

Страница 39: ......