Inspection (Figs.17 and 21)

Maintenance

Sleeve

Nut

Tube

10mm

Fig. 23

Fig. 22

Fig. 21

Lubrication port

Oil tank

Oil level gauge

19

12-6

Check & Maintenance of Hydraulic System

a)

Check motor and pump for any damage.

b)

Check hoses and pipings for proper tightness

and make sure that there is no leakage.

c)

Checking Nylon tubes for hydraulic oil intake

and drain:

Retighten brass nut if it is loosened and

leakage is noticed around. If the leakage

continues after retightening, replace the

Nylon tube, nut and sleeve with a set of new

ones.

d)

Check oil tank for proper oil level and see if

the hydraulic oil has not been whitened or

emulsified.

Its whitish color means aeration in pump.

Re-tighten piping and correct the level of oil.

Emulsification means water in the hydraulic

oil. Replace the oil.

a)

Oil filter replacement (Fig.22)

Initial replacement: After 25 hours of operation

Thereafter: In every 500 hours of operation

CAUTION:

Use genuine Mikasa filter paper

with 10 microns only. Replace it if suction

resistance has exceeded 254mmHg. (at

operating temperature of 60 degrees C)

b)

Hydraulic oil replacement

Though it depends on load, normally it should

be replaced in every 1,000 to 1,500 hours of

operation. Remove drain plug off oil tank and

hose joint to drain old oil before refilling it with

25 liters of recommended oil. Use care not to

allow dust, foreign matter or water to enter.

CAUTION:

Dispose of the oil which pulled out

as the appropriate waste done regulations of.

Recommended wear resistant hydraulic oil:

Viscosity: ISO VG32 equivalent, for cold

region

ISO VG46 or 56 equivalent, for general

and warm region

(At the factory shipment, machine is filled with

Shell Tellus 46.)

Installation

a)

b)

c)

1/4 (pipe thread) hydraulic hose tightening torque:250kg-cm

1/4 (pipe thread) hydraulic hose tightening torque:380kg-cm

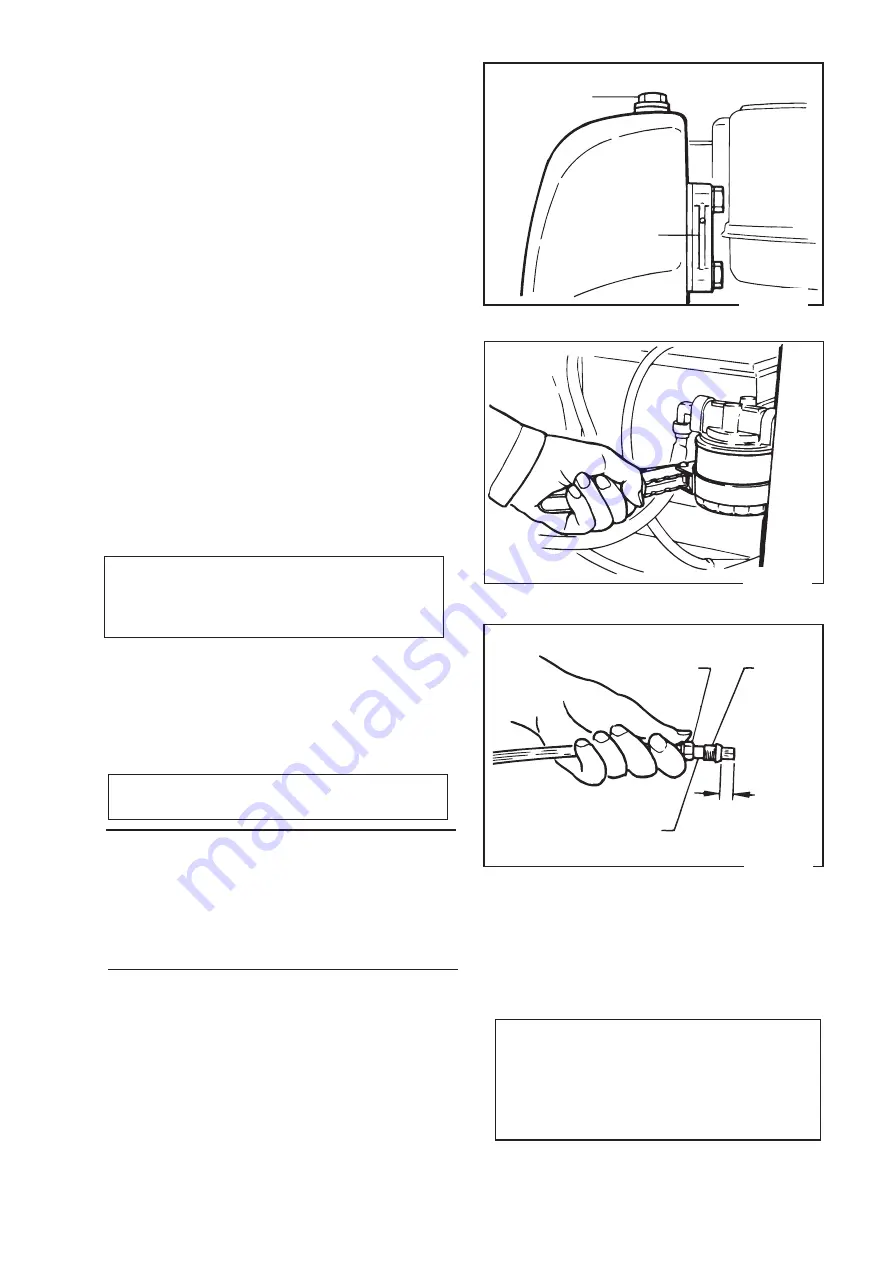

Installing the Nylon tube (Fig.23)

●

Insert nut and sleeve to the Nylon tube.

●

Nylon tube should extend from sleeve end by

about 10mm.

●

Insert the Nylon tube straight all the way into

connection of the joint.

●

With the Nylon tube thus inserted, tighten nut

fully with fingers. Then, tighten it further with

wrench to leave 1 -1.5cm of thread of joint

remaining.

(Tightening torque: 100 -140kg-cm)

These are the two points to be carefully

watched during replacement work.

CAUTION:

●

Watch for insufficient depth of insertion

for sleeve and Nylon tube into joint.

●

Watch for insufficient tightening of nut.

Содержание MRH-600DSA-DX

Страница 1: ...MRH 600DSA DX INSTRUCTION MANUAL 502 02702 WITH ELECTROMAGNETIC CLUTCH VIBRATION ROLLER...

Страница 23: ...21...

Страница 27: ......

Страница 28: ...502 02702 Jan 11 BSC...