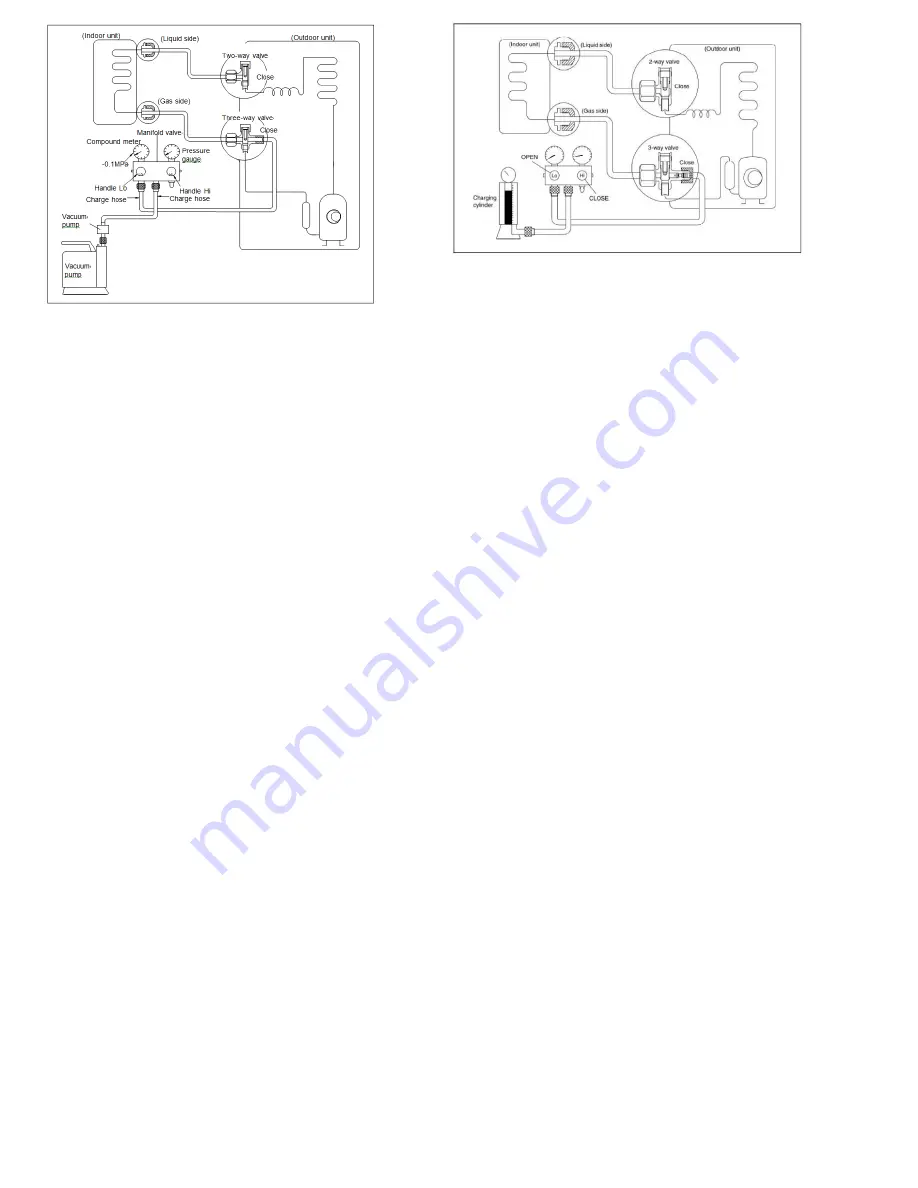

1. Completely tighten the flare nuts of the indoor

and outdoor units, confirm that both the 2-way

and 3-way valves are set to the closed

position.

2. Connect the charge hose with the push pin of

handle lo to the 3-way valves gas service

port..

3. Connect the charge hose of handle hi

connection to the vacuum pump.

4. Fully open the handle Lo of the manifold valve.

5. Operate the vacuum pump to evacuate.

6. Make evacuation for 30 minutes and check

whether the compound meter indicates -

0.1Mpa(14.5Psi). If the meter does not indicate -

0.1Mpa(14.5Psi) after pumping 30 minutes, it

should be pumped 20 minutes more. If the

pressure can’t achieve -0.1Mpa(14.5Psi) after

pumping 50 minutes, please check if there are

some leakage points. Fully close the handle Lo

valve of the manifold valve and stop the

operation of the vacuum pump. Confirm that the

gauge needle does not move (approximately 5

minutes after turning off the vacuum pump).

7. Turn the flare nut of the 3-way valves about

45° counterclockwise for 6 or 7seconds after

the gas coming out, then tighten the flare nut

again. Make sure the pressure display in the

pressure indicator is a little higher than the

atmosphere pressure. Then remove the

charge hose from the 3 way valve.

8. Fully open the 2 way valve and 3 way valve

and securely tighten the cap of the 3 way

valve.

2. Air purging by refrigerant

Procedure:

1). Confirm that both the 2-way and 3-way valves

are set to the closed position.

2). Connect the charge set and a charging cylinder

to the service port of the 3-way valve.

3). Air purging.

Open the valves on the charging cylinder and the

charge set. Purge the air by loosening the flare

nut on the 2-way valve approximately 45’ for 3

seconds then closing it for 1 minute; repeat 3

times.

After purging the air, use a torque wrench to tighten

the flare nut on the 2-way valve.

4). Check the gas leakage.

Check the flare connections for gas leakage.

5). Discharge the refrigerant.

Close the valve on the charging cylinder and

discharge the refrigerant by loosening the flare

nut on the 2-way valve approximately 45’ until the

gauge indicates 0.3Mpa(43.5Psi) to 0.5

Mpa(72.5Psi)..

6). Disconnect the charge set and the charging

cylinder, and set the 2-way and 3-way valves to

the open position.

Be sure to use a hexagonal wrench to operate the

valve stems.

7). Mount the valve stems nuts and the service port

cap.

Be sure to use a torque wrench to tighten the

service port cap to a torque 18N·m.

Be sure to check the gas leakage.

3. Adding refrigerant if the pipe length

exceeds chargeless pipe length

Содержание M2OC-18HFN1-M

Страница 19: ...8 Wiring Diagrams 8 1 Wiring diagram of 1 drive 2 outdoor M2OC 18HFN1 M M2OD 18HFN1 M...

Страница 20: ...PCB board of M2OC 18HFN1 M M2OD 18HFN1 M...

Страница 21: ...IPM board of M2OC 18HFN1 M...

Страница 22: ...IPM board of M2OD 18HFN1 M...

Страница 23: ...8 2 Wiring diagram of 1 drive 3 outdoor M3OD 27HRDN1 M M3OC 30HRFN1 M...

Страница 24: ...PCB board of M3OC 30HRFN1 M...

Страница 25: ...IPM board of M3OC 30HRFN1 M...

Страница 26: ...PCB board of M3OD 27HRDN1 M...

Страница 27: ...IPM board of M3OD 27HRDN1 M...

Страница 28: ...8 3 Wiring diagram of 1 drive 4 outdoor M4OC 36HRFN1 M...

Страница 29: ...PCB board of M4OC 36HRFN1 M...

Страница 30: ...IPM board of M4OC 36HRFN1 M...

Страница 31: ...PFC board of M4OC 36HRFN1 M...

Страница 66: ...IPM for dual tri zone IPM for qua zone P N for dual tri zone...

Страница 67: ...P N for qua zone...

Страница 68: ...bridge rectifier for dual tri zone bridge rectifier for qua zone...

Страница 69: ...Remark Measure the DC voltage between and port The normal value should be 190V 250V...

Страница 71: ...Two ports of the inductance Inductance...

Страница 72: ......

Страница 77: ......

Страница 79: ......

Страница 81: ......

Страница 83: ......

Страница 96: ...6 EXV check Disconnect the connectors...

Страница 97: ...Resistance to EXV coil Color of lead wire Normal Value Red Blue About 50 Red Yellow Brown Orange Brown White...

Страница 98: ...Red Blue Red Yellow...

Страница 99: ...Brown Orange Brown White...

Страница 114: ...Screws of front panel Screws of right rear panel Screws of top cover...

Страница 122: ...Screws of big handle Screws of right rear panel Screws of water collector Screws of terminal board...

Страница 128: ......