11

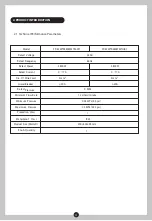

6. TROUBLESHOOTING

SUGGESTIONS

1. Check whether power is cut

2. Contact authorized service

personnel for repair.

3. Make sure the grounding is

reliable.

1. Rotate “TEMP” knob

2. Repair or replacement

of the PCB

1. Press the reset handle

of the thermal sensor

after checking and

troubleshooting

2. Change the heating

element

3. Adjust water flow

4. Change the flow sensor

5. Open the flow sensor

and clean the rotor

1. Wait for restoration of

running water supply;

2. Open the inlet valve of

running wate r.

Lower the heating power and

increase the water flow.

Contact authorized service

personnel for repair.

Contact authorized service

personnel for repair.

REASONS

1. Power supply error,

2. PCB error;

3.

4.

Occurence of leakage current

There is no ground electrode or

incorrect ground connection

1. The “TEMP” knob is off;

2.

3. The water flow

is below 1.2L/min;

PCB error ;

4. Impurities clogging the

flow sensor of the rotor

1. The running water

supply is cut off;

2. The inlet valve of running

water is not open.

1. Water p ressu re is not

stable.

2. Outlet water temperature

is too high, overheating

protection activates repeatedly

Occurence of electrical

current leakage.

PUMP malfunction.

Temperture sensor

is broken

Change the temperture

sensor

SYMPTOMS

The heating indicator light

is off and the outlet

water is cold.

The heating indicator light

is on and the outlet

water is cold.

Switch on the power

supply, ELCB indicator

light is o ff.

No water flows out of

the shower head.

Outlet water temperature

is sometimes hot or cold

Pressure can’t be

increased.

1. The thermal sensor

cut off the circuit

2. Heating element

is broken

“EARTH”

、

“ELCB”and

“POWER” indicator

lights flicker at the

same time

“POWER” indicator light

flickers

5. MAINTENANCE

DECLARATION:

this water heater can only be maintained by authorized service personnel.

Incorrect installation and use may cause serious injury or loss of property.

WARNING

Do cut off power supply before maintenance, to avoid danger such as electric shock.

!

This electric water heater should be installed in a place without direct sunshine or where

rainwater will not hit the unit. Please cut off power supply if the unit will not be used for a

long period of time.

Please run the water for about 10 seconds to drain away the impurities in the pipe before

connecting the water source to the electric water heater, to avoid clogging.

If the unit has not been used for a long time, check it first before using it again. Turn on the

unit only after water constantly flows out of the shower head.

Do not spray water to the circuit breaker or heater body directly, to avoid moisture formation.

Please cut off the power during inclement weather to avoid damaging the water heater.

If the unit will not be used for a long period of time, turn off the water supply to the water heater,

to prolong its life.

Check the power cord connecting terminals frequently to make sure that these are well and

reliably contacted, no occurence of overheating phenomenon, and grounding is good.

Disassemble the shower head and sealing ring with filter, for periodic cleaning.