(3) and one seat (5) may fall out. If not, use a piece of

wood or some other soft material to gently tap the ball

from the non-insert end of the valve.

6. Carefully remove the bottom seat (5) out of the body,

BEING CAREFUL NOT TO SCRATCH THE BODY

SEALING SURFACE BEHIND THE SEAT.

NOTE: On ½” (DN15) valves, the stem cannot be removed

with the stem seals and body seat in place.

7. Press the stem (4) and lower stem seal into the valve

body cavity and remove the upper stem seal. Then

remove the stem and lower stem seal together from

the valve body. It may be necessary to tap the stem

with a piece of wood or some other soft material.

8. Remove the all stem seals (8) and/or (7 & 24), BEING

CAREFUL NOT TO SCRATCH ANY SEALING SURFACE

INSIDE THE STEM BORE.

4.5

Checking Parts

1. Clean all disassembled parts.

2. Check the stem (4) and ball (3) for damage. Pay

particular attention to the sealing areas.

3. Check all sealing and gasket surfaces of the body (1)

and insert (2).

4. Replace any damaged parts.

5. Replace any fastener where the threads are damaged

or have been heated, stretched or corroded.

6. Replace any parts that have cracks, gouges or pits that

will affect sealing.

NOTE: When ordering spare parts, always include the

following information:

a. Valve catalog code from Identification plate,

b.

If the valve is serialized – the serial number

(stamped on the valve body),

c. From Figure 10, the ballooned part number, part

name and quantity required.

4.6

Assembly

It is advisable to replace seats and seals if complete

disassembly and reassembly become necessary. Refer to

the Repair Kit chart (see Table 3 or 4). A good lubricant,

compatible with the flow media, MUST be applied to the

threads on insert (2) to prevent galling during assembly.

Lubricant should also be applied to the seats, seals, ball and

stem to facilitate assembly and ease on initial operation of

the valve.

Clean all valve components if not done previously.

Re-inspect all components for damage before reassembling

the valve. Look for damage to the seating areas, stem, body

and insert; and look for wear in the bearing areas. Replace

any damaged parts.

Carefully clean and polish the ball (3) sealing surface: It

should be free of all scratches and grooves.

If the ball is slightly damaged, it may be possible to smooth

the sealing surface with crocus cloth or equivalent. If deep

scratches are present, replace the ball.

1. ½” (DN15) Series 5000 Valves

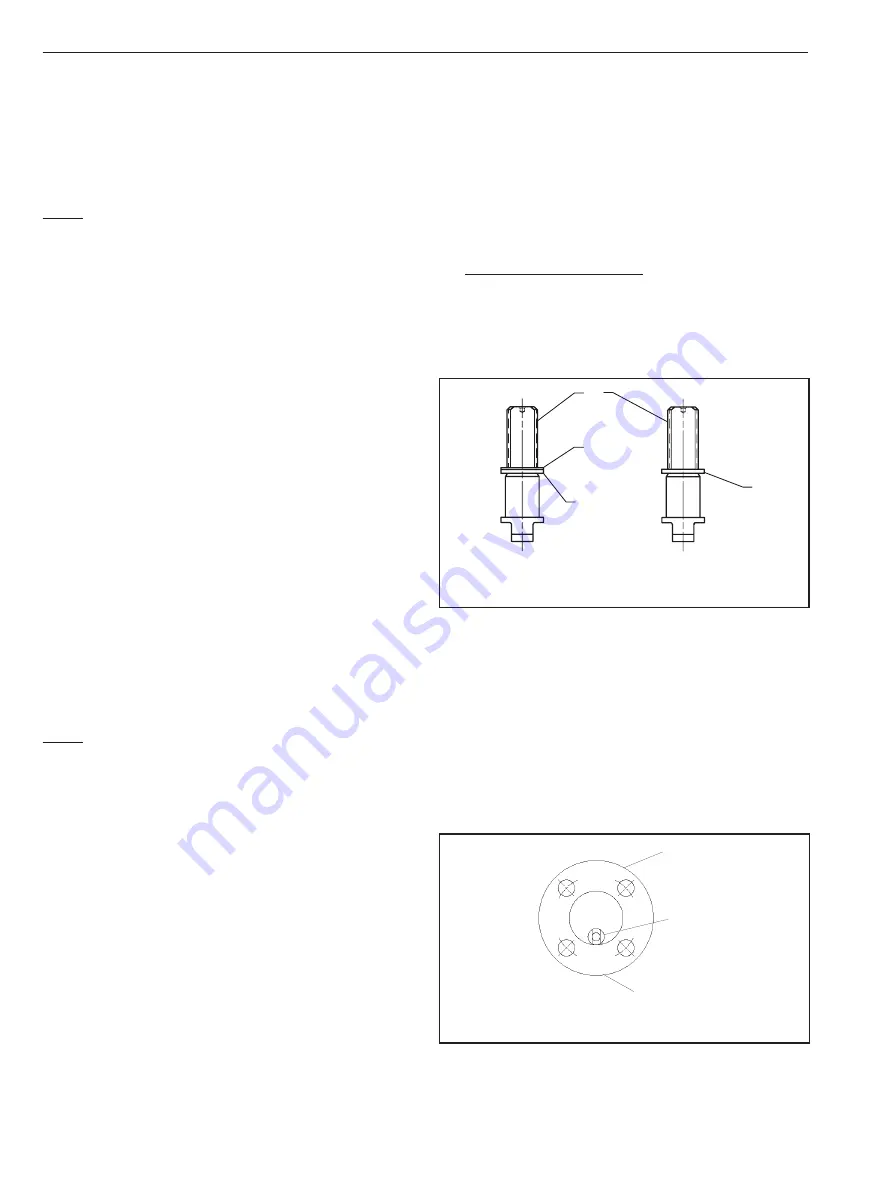

A. Slide the lower stem seal (24) and secondary

stem seal (7) (for fire-tested valves), or lower

stem seal (8) (for non-fire-tested valves), over the

threaded portion of the stem (4). The stem and seal

subassembly must look like Figure 5.

B. Place the body (1) on a flat surface resting it on

both flanges with bonnet facing down.

C.

Slide the stem and stem seal subassembly,

threaded-end first, along the inside of the body

bore towards the stem hole. The blade at the ball

end of the stem must be vertical as seen from the

insert end of the valve (see Figure 6). When the

threaded end of the stem reaches the stem bore,

guide it down into the bore and swing the entire

subassembly up into the vertical position, allowing

it to fall into place.

D. Roll the entire valve on its flanges until the bonnet

faces up. Then rotate the stem ¼ turn. The stem

subassembly should look like (Figure 7) as seen

from the insert end of the valve.

4

7

8

24

Fire-Tested

Non-Fire-Tested

Figure 5 Stem and Seal Subassembly

Body

Stem

Bonnet of Valve

Figure 6 Ball end of stem

IMO 4/18

6

IMO-50 EN