Maintenance

03.05.2018

page 20

Maintenance Plate rolling machine RBM 610-8 ; Version 1.05

©

20

18

GB

5

Maintenance

This chapter contains important information

- Inspection,

- Maintenance,

- Repair.

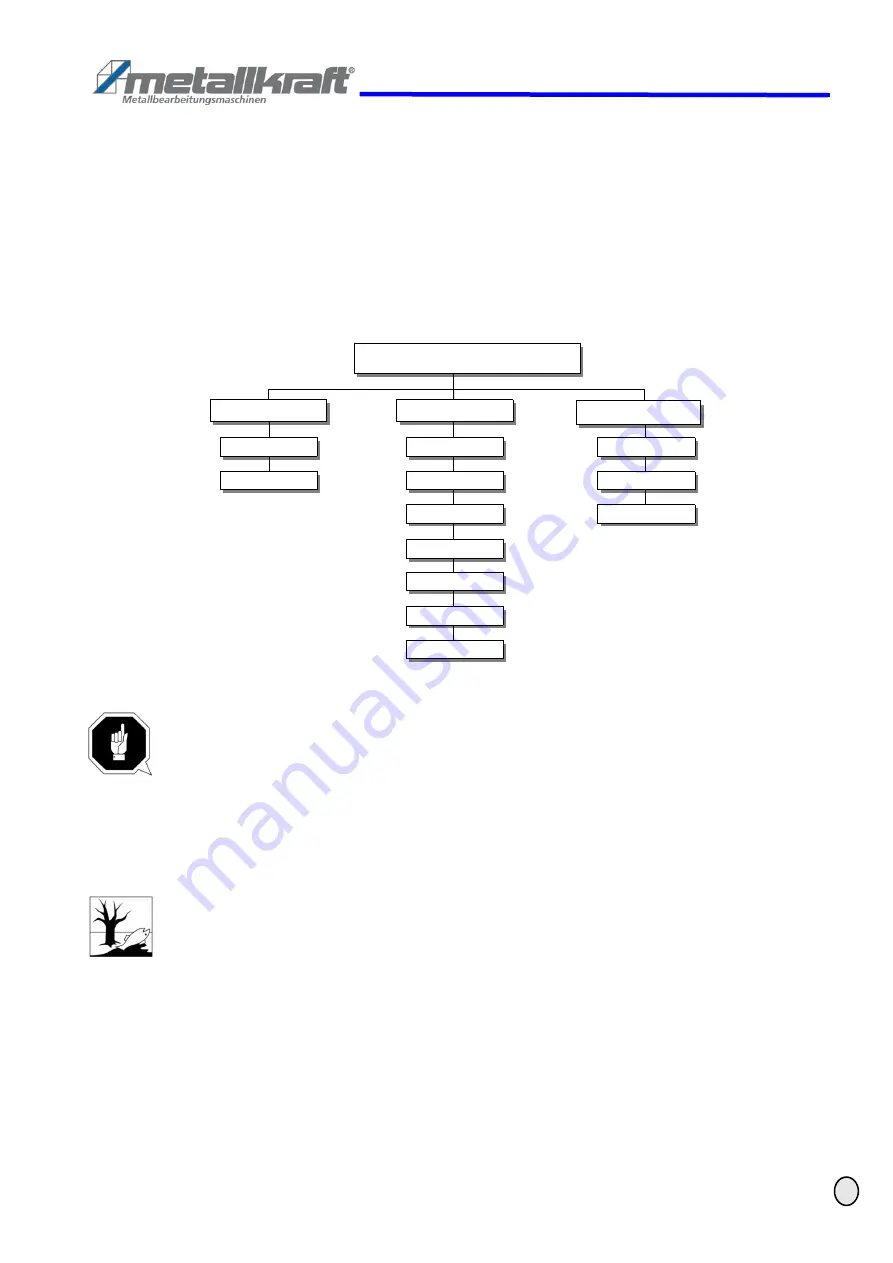

The diagram shows you which works fall under these terms.

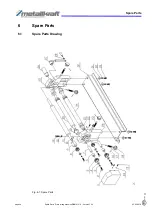

Fig.5-1: Maintenance

CAUTION!

Regular, properly performed maintenance is an essential requirement for

• the operational safety,

• trouble-free operation,

• a long life of the machine and

• the quality of the products you produce.

The equipment and devices of other manufacturers must be in perfect condition.

ENVIRONMENT PROTECTION

Be careful when working on the bending head

• Can be used, the capacity of which is sufficient for the amount of liquid to be collec-

ted.

• Liquids and oils do not fall into the soil.

Immediately tie spilled fluids and oils with suitable oil absorbents and dispose of them in

accordance with the applicable environmental protection regulations.

Catching leaks

Do not return fluids that are generated during repair or leaks outside the system to the reservoir

but collect them in a collection container for disposal.

INSTANDHALTUNG

Inspektion

Wartung

Instandsetzung

Messen

Säubern

Ausbessern

Prüfen

Reinigen

Austauschen

Konservieren

Schmieren

Ergänzen

Auswechseln

Nachstellen

Einstellen

Maintenance

Inspection

Measure up

Check

Service

Clean

Washing

Conserve

Lubricate

Recruit

Replacement

Readjust

Reconditioning

Refinishing

Replace

Setting