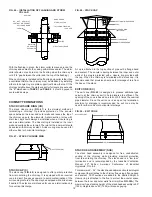

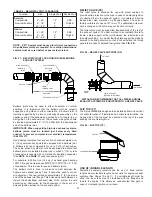

FIG. 40 – STACK SUPPORT ASSEMBLY INSTALLATION

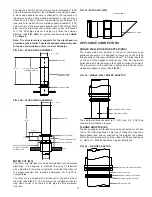

VENTILATED THIMBLE ASSEMBLY (VTA) AND ROOF

SUPPORT ASSEMBLY (RSA)

The ventilated thimble assembly is designed to allow Model

PIC/IPIC chimney to penetrate a combustible roof at a nominal

3” clearance to combustibles.

FIG. 41

illustrates the required

minimum framing dimensions. The ventilated thimble is intended

for installation on a flat roof. It may be used on a pitched roof if a

curb is installed at the penetration to provide a level surface for

mounting the thimble.

FIG. 41 – ROOF FRAMING FOR VENTILATED THIMBLE

ASSEMBLY OR ROOF SUPPORT ASSEMBLY

Model

PIC & IPIC-1

IPIC-2

IPIC-4

“X”

I.D. + 8” (203) I.D. + 10” (254)

I.D. + 14” (356)

The roof support assembly is a special variation of the ventilated

thimble which also provides vertical support to the chimney. It is

especially useful when the chimney rise below the roof is long

enough to cause movement from thermal expansion to exceed

approximately 2” (51).

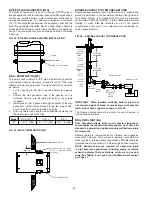

The ventilated thimble consists of the thimble with 4 support

brackets; 2 lateral support rings, split for ease of installation; a

flashing; a storm collar.

Installation of the ventilated thimble is as follows (See

FIG. 42

):

1. Cut the roof opening and reinforce the edges of the hole

as appropriate for the expected load bearing requirements.

Attach the thimble brackets to the thimble using the

hardware provided.

2. Set the thimble through the roof, making sure it is centered

in the roof penetration hole, and secure it to the roof deck

with bolts or lag screws supplied. The brackets may be

welded to a metal roof, if desired.

3. Install the chimney passing through the thimble and

extending above the roof.

4. Install the 2 split lateral support rings on the chimney casing,

one above the thimble and one below the thimble. Leave

the bolts loose enough to allow the ring to slide along the

casing. The spacer tabs are to be toward the thimble.

5. Push the lateral rings along the chimney casing until they

are completely enclosed in the thimble.

6. Install the flashing centered on the thimble. Secure it to the

roof and seal it to the roof membrane as appropriate.

FIG. 42 - VENTILATED THIMBLE ASSY. INSTALLATION

“X”

“X”

16

EXIT CONE

FULL ANGLE RING

BRACING (BY OTHERS)

NOTE: DO NOT USE VARIABLE LENGTH OR

EXPANSION JOINT BETWEEN BREECHING &

STACK SUPPORT ASSY.

STACK SUPPORT ASSEMBLY

CONCRETE PAD OR

STRUCTURAL BASE

BREECHING

90° TEE

LATERAL SUPPORT RING

FLASHING

STORM COLLAR

SUPPORT BRACKET

THIMBLE

LATERAL SUPPORT RING

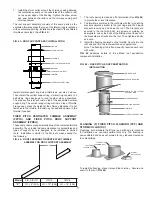

STACK SUPPORT ASSEMBLY (SSA)

The stack support assembly is intended for use as a base mount

for mounting the stack on a concrete floor or a structural steel

stand. It is equipped with a predrilled steel baseplate for the

insertion of anchor bolts or studs. A 9-inch section of pipe is

attached to the baseplate and contains a false bottom 4½” (114)

above the floor. A 1” (25) NPT nipple extends through the side of

the pipe section just above the false bottom to allow drainage of

rain or condensate (See

FIG. 39

). It is recommended that a 90º

manifold tee with a cleanout cap be installed above the stack

support to provide access to the stack.

When using a stack support assembly as the stack base, it is

important to use exact pipe lengths to raise the stack height to

the breeching connection point (See

FIG. 40

). Use of variable

lengths or expansion joints in the stack under the breeching

connection defeats the purpose of the stack support assembly.

These components will not support weight.

FIG. 39 – STACK SUPPORT ASSEMBLY

1” N.P.T. NIPPLE