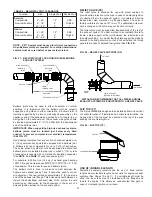

FIG. 28 – PLATE SUPPORT BRACING REQUIREMENTS

“X” is a minimum of 30° when bracing is used. A welded frame

must be adequately attached to structural member for framework

rigidity if bracing isn’t used.

Pipe

Diameter

PS Plate

Thickness

Bracing for (PS) Plate Support

Height of Stack

50’ (15.24m) 100’ (30.48m)

6” - 20”

3/16” (5)

1 1/4”x1 1/4”x1/8”

(32x32x3)

2”x2”x1/4”

(51x51x6)

22” - 36”

1/4” (6)

2”x2”x1/8”

(51x51x3)

3”x3”x1/4”

(76x76x6)

38” - 48”

1/4” (6)

3” (76) channel: 3”x1 1/2”x1/4”

(76x38x6)

Pipe

Diameter

PS Plate

Thickness

Framework for (PS) Plate Support

Height of Stack

50’ (15.24m) 100’ (30.48m)

6” - 20”

3/16” (5)

1 3/4”x1 3/4”x1/8”

(44x44x3)

3”x2”x3/16”

(76x51x5)

22” - 36”

1/4” (6)

2”x2”x1/4”

(51x51x6)

4”x3”x1/4”

(102x76x6)

38” - 48”

1/4” (6)

3” channel: 3”x1 1/2”x1/4”

(76x38x6)

When the supported section is subject to thermal expansion

or is in a vertical position, so that the plate support is weight

bearing, the support structure must be braced with diagonal

members or gussets to prevent deflection of the supported joint

(See

FIG. 28

). Plate supports are usually located adjacent

to fittings, such as tees or elbows, to protect the fitting from

expansion stresses. Chimneys heights in excess of a single

plate support capability can be resupported with additional plate

support(s). An expansion joint must be used between support

points (See

FIG. 29

).

FIG. 29 – RESUPPORT REQUIREMENTS

A plate support assembly is to be attached only to

non-combustible construction such as block, concrete or steel

with clearance that is adequate for installation and access.

DO NOT ATTACH THE PLATE SUPPORT TO COMBUSTIBLE

CONSTRUCTION.

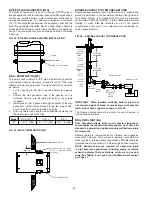

For maximum support, the entire perimeter of the plate support

assembly must be attached to structural framing (See

FIG. 30

).

Structural members are supplied by the installer.

FIG. 30 – SECTIONAL DETAIL FOR PLATE SUPPORT

PLATE SUPPORT

EXPANSION JOINT

FULL ANGLE RINGS

PLATE SUPPORT

EXPANSION JOINT

FULL ANGLE RINGS

PLATE SUPPORT

TO APPLIANCE

DRAIN

TEE CAP

90° TEE

200 FT. (60.96M)

MAXIMUM

100 FT.

(30.5M)

FLUE

CASING

FLANGE

BAND

CLAMP

RING

PLATE

13

STRUCTURAL BRACING

(BY OTHERS)

PLATE SUPPORT

CLAMP RING

BRACING

(BY OTHERS)

“X”

PIPE SECTION

PIPE SECTION

EXHAUST

FLOW

PLATE SUPPORT (PS)

NOTE: See TABLE 5 for maximum supported height.

The plate support assembly is designed to provide maximal

support to vertical sections and to provide fixed-point support for

horizontal sections. The plate support must be attached to the

building structure or support with rigid structural members.

NOTE:

Clamp ring sections and plate sections install at

90° angles.