24

ENGLISH

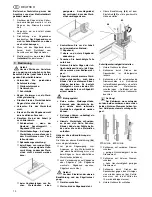

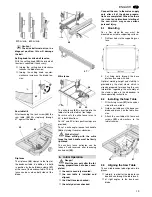

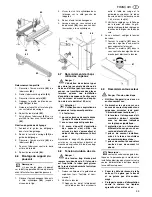

Adjusting the thrust bearing

1.

Loosen the thrust bearing's lock

screw

(87)

.

2.

Adjust thrust bearing position

(88)

(distance thrust bearing - band saw

blade = 0.5 mm – if the band saw

blade is turned by hand, it must not

touch the thrust bearing).

3.

Tighten the thrust bearing lock

screw

(87)

.

Adjusting the guide bearings

1.

Loosen screws

(89)

.

2.

Set guide bearings

(90)

against the

band saw blade.

3.

Turn the band saw wheel by hand in

a clockwise direction several times

to bring the guide bearings in correct

position – both guide bearings

should

just touch

the band saw

blade.

4.

Tighten screws

(89)

again.

5.

Close lower blade guard

(85)

6.

Close the lower housing door.

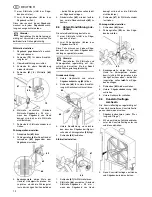

8.5

Replacing the Band Saw

Tyre

Periodically check band saw tyres for

wear. Replace only in pairs:

1.

Remove band saw blade (see "Care

and Maintenance");

2.

Lift band saw tyre with a small

screwdriver, then pull off the band

saw wheel.

3.

Mount new band saw tyres and rein-

stall the band saw blade.

8.6

Replacing the Table

Insert

The table insert needs replacement

when its slot has become enlarged or

damaged.

1.

Remove table insert

(91)

from saw

table (push up from underneath).

2.

Fit new table insert.

8.7

Adjusting the Blade

Guard's Movement Rate

Adjust the movement rate of the blade

guard if it can be lowered too easily.

1.

Pry the cover of the blade guard

adjusting knob off with a screw-

driver.

2.

Tighten the hexagon nut inside the

knob.

3.

Fit the cover back on the adjusting

knob.

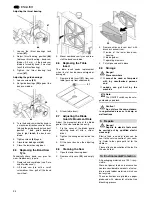

8.8

Cleaning the Saw

1.

Open the lower housing door.

2.

Remove chip case

(92)

and empty

it.

3.

Remove chips and saw dust with

brush or vacuum from:

inside of the lower band saw

housing;

blade guides;

operating elements

4.

Put chip case back in place.

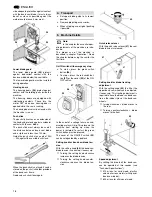

8.9

Storage

A

Danger!

Store saw where

it cannot be used or tampered

with by unauthorized persons

and

nobody can get hurt by the

machine

.

3

Note:

The ON/OFF switch can be safe-

guarded by a padlock.

A

Caution!

Do not store the saw outdoors,

in unprotected areas or in damp or

wet locations.

A

Danger!

Repairs to electric tools must

be carried out by qualified electri-

cians only!

Electric tools in need of repair can be

sent to the service centre of your coun-

try. Refer to the spare parts list for the

address.

Please attach a description of the fault to

the electric tool.

All packaging materials are 100% recy-

clable.

Worn out power tools and accessories

contain considerable amounts of valua-

ble raw and rubber materials, which can

be recycled.

These instructions are printed on paper

produced with elemental chlorine-free

bleaching process.

87

88

89

90

91

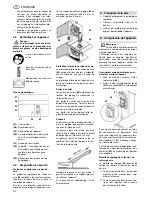

9.

Repairs

10. Environmental Protection

92

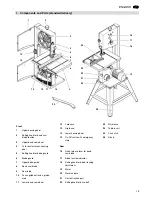

Содержание BAS 317 Precision WNB

Страница 53: ...ZA0091_1 fm 3 1 2 4 6 5 ...

Страница 54: ......

Страница 55: ......

Страница 56: ...U4BA_M1 FM ZINDEL AG Technische Dokumentation und Multimedia www zindel de www metabo com ...