mcr DOR smoke control dampers

„MERCOR” S.A.

– The company reserves the right to modify and change the document.. Version: mcr DOR 22.05.04.1

7/16

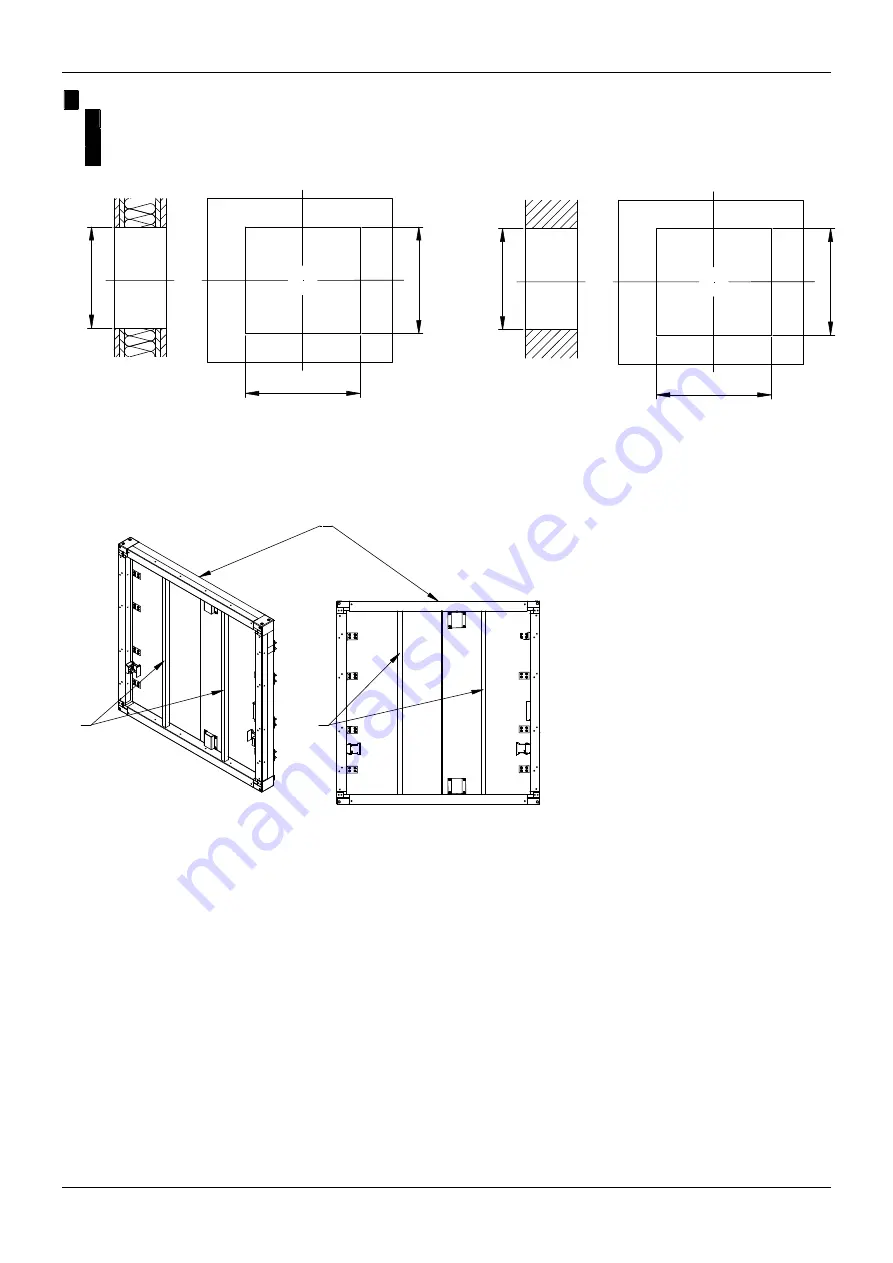

Installation in the duct in accordance with EN1366-8 and EN1366-9, passing through the wall:

fire-proof board thickness 40mm:

X min. = 85mm

fire-proof board thickness 50mm:

X min. = 105mm

fire-proof board thickness 60mm:

X min. = 125mm

H

+

X

B + X

H

+

X

B + X

H

+

X

H

+

X

Preparation of the installation opening.

6.3.

EMBEDDING / FIXING THE DAMPER

2

2

1

1. Damper mcr DOR BxH

2. Wooden blocks

Protecting the damper against buckling.

The mcr DOR damper will work properly if the partition rotation axis is horizontal. The trigger control

gear may be located on the right or on the left hand side of the damper at any direction of air flow.

Before embedding/fixing, place the damper axially aligned within the partition in the finished installation

opening. Level the device and secure in place. The gap between the flap housing, and the wall should be

thoroughly filled with the appropriate mortar, ensuring fire resistance of the wall and damper, paying special

attention so that it does not get to the executive elements of the flap (release and control mechanism,

partition, seals, limiters). To this end, before assembly, the flap must be strictly protected with foil or other

protective material until the end of masonry and finishing works. The partition must remain closed until the

mortar is tied. After binding the mortar, remove the brackets and re-open and close the flap to check the

correctness of its operation. In the case of mounting the damper in the wall of the boards, the space

between the damper housing and the wall should be tightly filled with mineral wool, having an A1 non -

reality class confirmed by a certificate, and density and thickness ensuring fire resistance not less than the

resistance of the wall in which the damper is installed. The filled space should be additionally sealed with

an appropriate mortar or putty with fire resistance required for the wall.

Connecting the inserted damper to the ventilation duct must be made in co-coaxial. When installing the

damper in the partition, the damper body can not be damaged, and in particular to the formation of