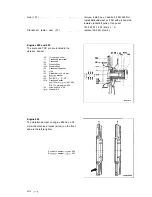

Gauge (01)

preignition chamber bore and set

dial gauge (07) on gauge to 5 mm pretension

(item 2).

Note

If cylinder head is removed, position gauge pin

of dial gauge directly on piston crown (177).

Use dial gauge holder 363 589 02 21 00.

Engine

turn in running direction until dial gauge pointer

stops moving (TDC position), set dial gauge

scale to zero (item 3).

Engine

turn until dial gauge moves back 3.22 mm

on engines 602 and 603 or until dial gauge

moves back 3.65 mm on engines 601.921,

603.97 (item 4).

Note

Corresponds to crankshaft position of

ATDC.

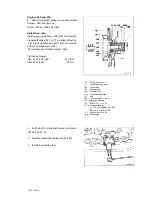

Holder for TDC sensor (42) or (44)

install locating device 603 589 01 21 00

(item 5).

Note

The pin on the crankshaft pulley or on the

vibration damper must catch in the groove on

the locating device, if not, correct position of

holder.

Holder for TDC sensor (42) or (44)

correct by loosening bolt

move holder for

TDC sensor until pin on crankshaft pulley or

vibration damper catches in locating device

603 589 01 21 00 and tighten bolt (41)

(items 6 8).

03.10

Содержание 602

Страница 1: ...Mercedes Benz Mercedes Benz of North America Inc Montvale NJ 07645 ...

Страница 5: ...General technical data 00 ...

Страница 15: ...Crankcase and Cylinder Head 01 ...

Страница 22: ......

Страница 33: ......

Страница 89: ......

Страница 140: ......

Страница 166: ... Special tool Note When testing and reconditioning crankshafts proceed in sequence shown in diagram below 03 10 31813 ...

Страница 191: ...This page int ntiowally left blank 03 10 32113 ...

Страница 217: ...Flywheels for manual transmissions Engine 602 D 252 94 252 98 mm Dl 223 00 223 07 mm H 57 mm 03 10 41013 ...

Страница 227: ...ine Timing Valvstr ...

Страница 282: ...Special tool f 05 10 310 5 ...

Страница 301: ...ystern Air r Turbocharger 09 ...