Page 8

L2

L1

L3

G

N

D

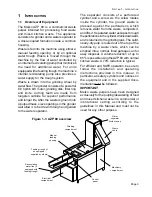

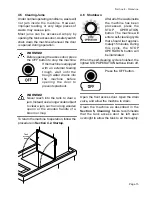

3.6 Main Electrical Supply Connection

WARNING!

Check that the circuit breaker/fused

disconnect is in the OFF position and

that the unit is switched off before

making the electrical utility connec-

tions.

IMPORTANT

In some cases, local codes dictate that

electrical supply connections be made only

by a certified professional.

1. Check that the incoming power leads are

of sufficient rating for the appliance’s

current draw. Amperage and minimum

supply wire specifications are shown on

the serial plate and on the electrical infor-

mation label inside the control box.

2. Remove the cover panel from the

electrical control box by removing the four

screws that hold it in place.

3. Locate the strain relief for the electrical

supply wiring on the back of the control

box (Figure 3-3). Thread the incoming

supply leads through the strain relief and

to the main electrical supply terminal block.

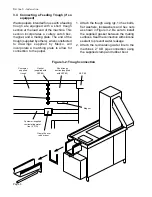

4. Refer to Figure 3-4. Connect the power

supply and ground leads as indicated.

5. Adjust the strain relief to fasten the wiring

in place. You should leave enough slack

in the wiring to prevent stress on the

terminal connections.

S

ECTION

3 - I

NSTALLATION

Figure 3-4: Main electrical supply

connections

GND = ground

L1, L2 and L3 = “hot” (line)

Internal chassis

ground.

Do not connect

supply ground to

this terminal

block.

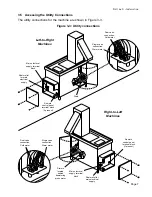

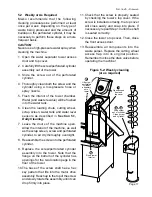

3.7 Remote Control Box Installation (if so

equipped)

WARNING!

Check that the circuit breaker/fused

disconnect is in the OFF position and

that the unit is switched off before

making the electrical utility connec-

tions.

IMPORTANT

In some cases, local codes dictate that

electrical connections be made only by a

certified professional.

1. If the machine is equipped with the

optional remote control box, fasten the

remote control box in place in the desired

location. Then, remove the four screws

that hold the cover panel in place to

access the connections.

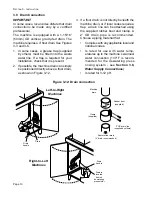

2. Locate the remote terminal block inside

the AZP 80 main electrical compartment

(see Figure 3-4). Then, locate the

corresponding terminal block inside the

remote control box.

3. Route a cable with 10 conductors and a

ground (supplied by others - AWG 16

recommended) between the AZP 80’s

electrical compartment and the remote

control box. Strain reliefs are provided in

the back wall of the main AZP 80 electrical

compartment, and on the bottom of the

remote control box.

4. Connect the cable, making sure to match

each set of corresponding terminals

correctly. The remote control box draws

its power from the AZP 80. No additional

electrical supply connection is required.