Page 16

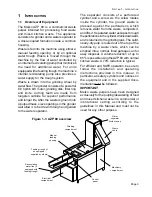

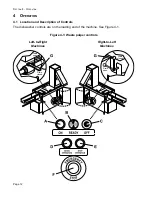

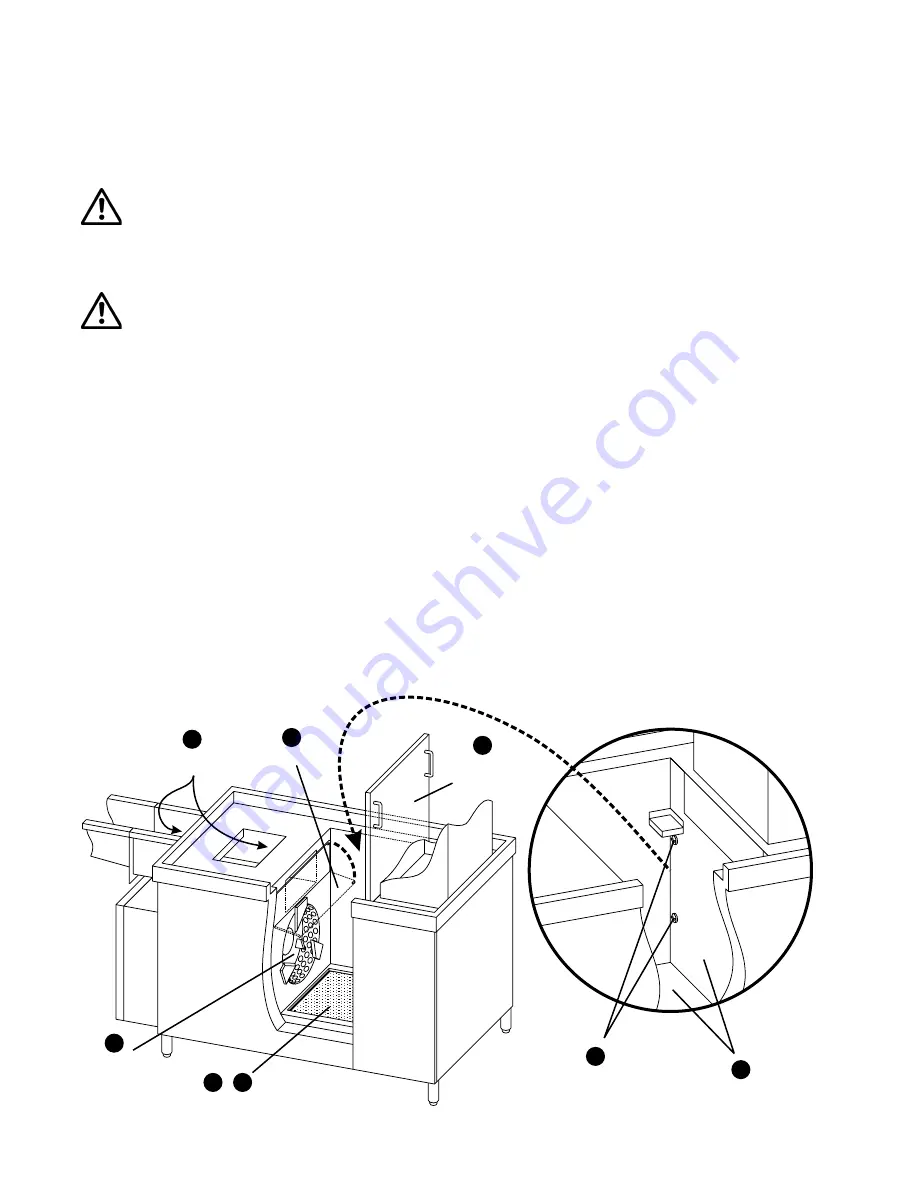

Open tank

access door

Flush chute

towards tank

2

Lift flap

Remove and clean scrap basket

3

1

4 5

-

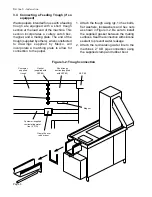

Flush

cutting

wheel

6

Clean tank

interior

7

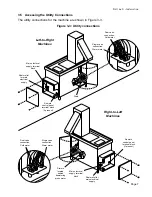

Clean level

sensors

(2)

8

S

ECTION

5 - C

LEANING

5

C

LEANING

For proper operation and effective cleaning,

the dishwasher should be cleaned regularly

as described below.

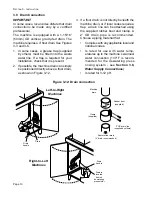

WARNING!

Before ANY cleaning, check that the

circuit breaker/fused disconnect is in

the OFF position and that the unit is

switched off.

WARNING!

Open the drain valve and allow the tank

to drain completely before cleaning.

CAUTION

Never use a high-pressure water spray when

cleaning the machine.

IMPORTANT

For easier cleaning, always allow the

machine’s self-cleaning rinse to finish before

shutting down the machine.

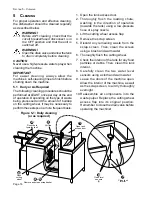

5.1 Daily or As Required

The following cleaning procedures should be

performed at LEAST once per day at the end

of operation. Depending on the type of waste

being processed and the amount of buildup

on the cutting wheel, it may be necessary to

perform these steps on a more frequent basis.

1. Open the tank access door.

2. Thoroughly flush the loading chute,

washing in the direction of operation

(towards the tank) using a low-pressure

hose or spray nozzle.

3. Lift the cutting wheel access flap.

4. Remove the scrap screen.

5. Discard any remaining waste from the

scrap screen. Then, clean the screen

using a brush and warm water.

6. Thoroughly flush the cutting wheel.

7. Check the interior of the tank for any food

particles or debris. Then, clean the tank

interior.

8. Carefully clean the two water level

sensors using a cloth and warm water.

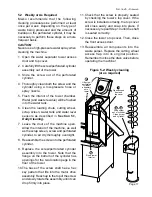

9. Leave the doors of the machine open.

Allow the interior of the machine, as well

as the scrap screen, to air dry thoroughly

overnight.

10.Reassemble all components into the

waste pulper. Replace the cutting wheel

access flap into its original position.

Remember to close the drain valve before

operating the machine!

Figure 5-1: Daily cleaning

(or as required)