Page 17

5.2 Weekly or As Required

Meiko recommends that the following

cleaning procedures be performed at least

once per week. Depending on the type of

waste being processed and the amount of

buildup on the perforated cylinder, it may be

necessary to perform these steps on a more

frequent basis.

CAUTION

Never use a high-pressure water spray when

cleaning the machine.

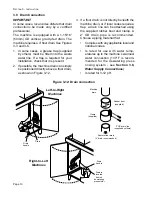

1. Open the water separator tower access

door and top cover.

2. Carefully lift the screw/perforated cylinder

assembly out of the tower.

3. Slide the screw out of the perforated

cylinder.

4. Thoroughly clean both the screw and the

cylinder using a low-pressure hose or

spray nozzle.

5. Flush the interior of the tower chamber.

Water (and waste residue) will be flushed

into the water tank.

6. Clean the loading chute, cutting wheel,

scrap screen, water tank and water level

sensors as described in

Section 5.1,

Daily Cleaning.

7. Leave the doors of the machine open.

Allow the interior of the machine, as well

as the scrap screen, screw and perforated

cylinder, to air dry thoroughly overnight.

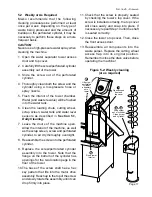

8. Reassemble the screw into the perforated

cylinder.

9. Replace the screw/perforated cylinder

assembly into the tower. Note that the

flange on the bottom of the cylinder has

openings for the two location pegs in the

floor of the tower.

10.The base of the screw shaft has a hex

key pattern that fits into the motor drive

assembly. Reach up to the top of the screw

and slowly rotate the assembly until it can

drop firmly into place.

11. Check that the screw is properly seated

by checking the tower’s top cover. If the

screw is installed correctly, the top cover

will close easily and snap into place. If

neccessary, repeat Step 10 until the shaft

is seated correctly.

12.Close the tower’s top cover. Then, close

the front access door.

13.Reassemble all components into the

waste pulper. Replace the cutting wheel

access flap into its original position.

Remember to close the drain valve before

operating the machine!

S

ECTION

5 - C

LEANING

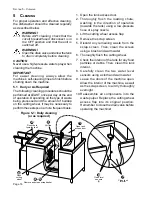

Figure 5-2: Weekly cleaning

(or as required)

Open access

door and

top cover

1

Lift screw/

perforated

cylinder

assembly

out of

tower

2

Slide screw

out of cylinder.

Clean screw

and cylinder

3 4

-

Flush tower

interior

5