10

12. Push the bottom stabiliser bar forwards and it will drop down and move towards you (see

machine parts drawing to enable you to locate the bar). Pass the bottom roll of dry film under the

stabiliser bar and back over the top of the roll of dry film then continue as in 10 above to separate

the polyolefin film from the dry film resist layer and to fix it to the bottom take up roller.

NB.

Do not push the stabiliser bar back into its original position.

13. Cut the excess lengths of the top and bottom dry film so that they just overlap the entry

point of the heated silicon rollers using the film cutter provided, a

sharp blade or scissors.

Using the roller height adjustment and pressure leaver at the right hand side of the

laminator open the rollers to the maximum gap and using a piece of card slightly wider

than the film and about 200mm in length push the card and two pieces of overlapping film

between the rollers. Then push the height adjustment leaver down until it is exerting

pressure on the card.

Turn on the power and set the Hot/Cold switch to cold and the Stop/Run button to run. Set the

speed to 1.4 metres per minute and press and hold down the load button until the card and dry

film have pass through the laminator. NB if you need to continue running just the film through the

machine you may need to move the leaver further down.

14. Replace the safety guard and feed tray and your laminator is ready to use.

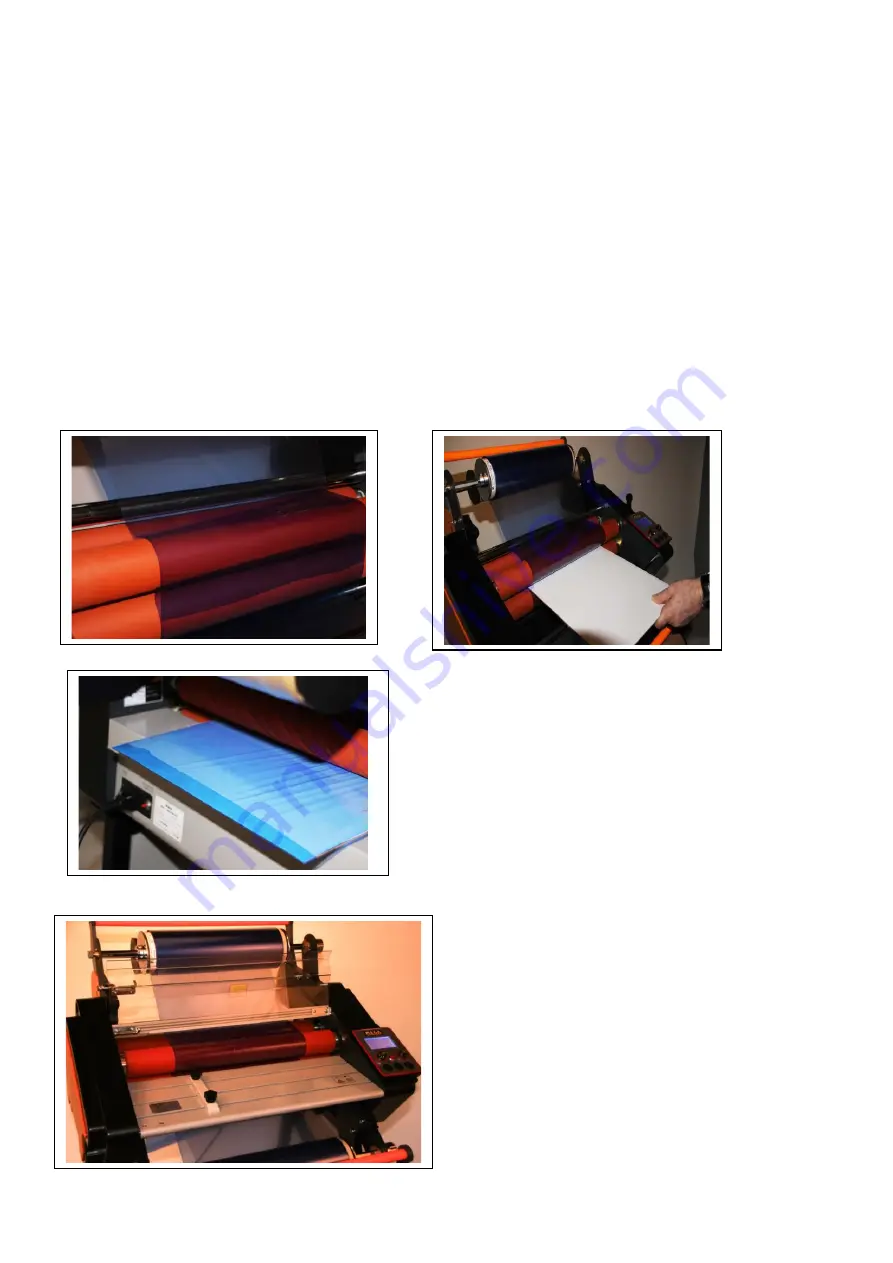

Finished loaded laminator.