McQuay IM 777-1

7

Installation Guidelines

Dampers and Hoods

Side dampers may be provided in the mixing box and

economizer sections of units. When dampers are provided, a

removable panel is located above the weather hood to provide

access to the damper drive shaft. Other access may be available

depending on the specific construction of the unit. See Figure 14.

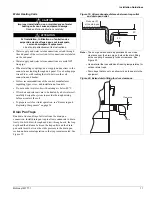

Figure 14: Filler panel over the weather hood

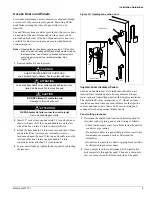

When units are ordered with exhaust hoods and intake hoods

adjacent to each other, install a field-supplied barrier to

prevent recirculation of exhaust air into the intake openings.

See Figure 15.

Figure 15: Field-installed barrier between hoods

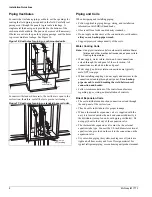

Mounting Actuators

The installing contractor is responsible for the mounting of all

field-installed actuators. No provisions are made for the

location of these actuators due to the number of options and

arrangements available and the variety of specific applications.

Typically, actuators are mounted inside the cabinet. Provide

proper support for the actuator to avoid excessive stress in the

cabinet, linkage, or damper shafts.

Note –

Damper blades are at full flow when open to 70 degrees.

Do not open blades further than 70 degrees.

Fresh air and return air dampers can be linked together and

driven from the same actuator if the dampers are the same size.

If the dampers are different sizes, they must be driven by

separate actuators and controlled appropriately. Exhaust

dampers are always driven by a separate actuator.

A typical rotary electric actuator can handle up to 40 sq. ft. of

damper. For pneumatic actuators, allow 5 in-lb per square foot

of damper area.

Face and Bypass Section Mounting

Internal and external face and bypass sections are mounted

together using the instructions for horizontal components and

do not require additional instruction. Skyline air handlers are

provided with a bypass duct that is integral to the unit

construction and requires no field assembly.

Face and bypass dampers may or may not be linked together.

When dampers are placed before a single bank of coils, they

always are linked together and require a single actuator. When

dampers bypass a stacked or staggered coil, the dampers are

not linked and require multiple actuators.

Face and bypass dampers have a torque requirement of

10 in-lbs per square foot of damper face area.

Remove screws

and panel to access

damper control shaft.

Hood

E x h a u s t

I n t a k e

B a r r i e r

CAUTION

Maximum damper rotation is 70°.

Maximum shaft torque is 205 inches/pound.

Greater rotation or torque can cause equipment damage.

ATTENTION

La rotation maximale des colets est de 70°.

Le couple (torque) maximum de l’arbre est de 205po/lb.

Une plus grande rotation (ou torque) peut endommager

l’équipement.

Содержание Skyline IM 777-1

Страница 32: ...30 McQuay IM 777 1...

Страница 33: ...McQuay IM 777 1 31...

Страница 34: ...32 McQuay IM 777 1...

Страница 35: ......