McQuay IM 777-1

15

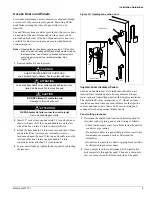

Operation Guidelines

7

Check alignment of fan and motor sheaves and belt tension.

Adjust if necessary. Check tightness of sheave setscrews

and/or capscrews. See Figure 35 and Figure 36 on page 24.

8

Leak test the thermal system to verify that connections are

tight.

9

Check that the condensate drain is trapped.

10

Rotate the shaft by hand to be sure it is free.

Fan startup:

Start and run fan. Observe the rotation. If the fan operates

backward, reverse two legs of the three-phase supply power.

Note –

Variable pitch fan drives usually are provided for operation

in the mid-speed adjustment range. However, the drives

usually ship with the adjustment opened up for minimum

fan speed. Adjust the drives for the proper airflow. See

“Fan Drive Adjustments” on page 20.

After the first 48 hours of operation:

1

Disconnect and lock electrical power source.

2

Check tightness of all bearing, wheel, and sheave setscrews

(or capscrews). See Table 6.

3

Recheck belt tension and adjust if necessary. Belts

tensioned sufficiently to slip one to two seconds at startup

will perform satisfactorily, extending life and reducing

vibration. If retensioning is necessary, be certain to retain

sheave alignment.

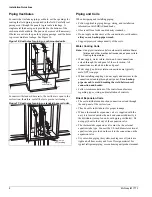

Fan Wheel Alignment

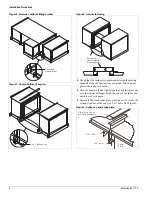

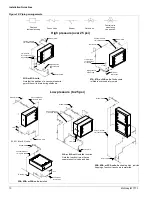

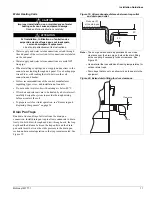

Figure 23: Wheel-to-inlet funnel relationship—airfoil type f

an wheels (housed)

Notes:

1. To obtain rated air performance, dimensional relationship must be held.

2. To obtain dimension A, loosen setscrews in wheel hub(s), shifting wheel(s)

axially as needed, and retightening setscrews.

3. To obtain dimension B, loosen screw and washer fasteners around

periphery of funnel(s), shifting funnel radially as required, and re-torquing

fasteners.

Figure 24: Wheel-to-inlet funnel relationship—forward

curved type fan wheels

Notes:

1. To obtain rated air performance, dimensional relationship must be held.

2. Adjust dimension C by loosening wheel hub set screws, shifting wheel(s)

axially as needed, and retightening set screws.

Table 2: Wheel-to-inlet funnel relationship—airfoil type

Airfoil

Unit sizes 003 to 035

Unit sizes 040 to 090

Dia.

A

(in)

A

(mm)

B

(in)

B

(mm)

Dia.

A

(in)

A

(mm)

A

(in)

B

(mm)

13.22 4.56

116

0.21

5.33 20.00 7.19

183

0.31

7.87

14.56 5.06

129

0.21

5.33 22.25 7.69

195

0.33

8.38

16.18 5.62

143

0.21

5.33 24.50 8.56

217

0.31

7.87

17.69 6.90

175

0.22

5.59 27.00 9.47

241

0.63 16.00

21.56 7.59

193

0.24

6.10 30.00 10.47

266

0.39

9.91

24.00 8.45

215

0.23

5.84 33.00 11.75

298

0.38

9.65

36.50 12.78

325

0.38

9.65

40.25 14.31

363

0.50 12.70

A

A

B

E q u a l s p a c i n g

a l l a r o u n d

Table 3: Wheel-to-inlet funnel relationship—forward curved

type fan wheels

Forward curved

Unit sizes 003 to 035

Unit sizes 040 to 090

Diameter \(in)

C (in)

C

(mm)

Diameter (in)

C (in)

C

(mm)

9 x 4

0.25

6.35

20 (Class 1 & 2)

0.24

6.10

9 x 7

0.13

3.30 22.38 (Class 1 & 2) 0.41

10.41

9 x 9

0.25

6.35

25 (Class 1 & 2)

0.47

11.94

10

0.22

5.59 27.62 (Class 1 & 2) 0.47

11.94

12

0.35

8.89

30 (Class 1 & 2)

0.47

11.94

15

0.44

11.18

33 (Class 1 & 2)

0.50

12.70

18

0.25

6.35

36 (Class 1 & 2)

0.75

19.05

20 (Class 1 & 2)

0.73

8.54

22 1/2 (Class 1 & 2) 0.59

14.99

24 1/2 (Class 1 & 2) 0.56

14.22

I n l e t

F u n n e l

W h e e l

C

C

I n l e t

F u n n e l

Содержание Skyline IM 777-1

Страница 32: ...30 McQuay IM 777 1...

Страница 33: ...McQuay IM 777 1 31...

Страница 34: ...32 McQuay IM 777 1...

Страница 35: ......