22

McQuay IM 777-1

Service and Maintenance

the other flange. Determine this by accurately measuring

the top width of the grooves.

7

Insert key

F

.

8

Tighten setscrews

D

and capscrews

E

.

9

Put on belts and adjust belt tension.

Do not force belts

over grooves.

See “Fan Drive Belt Adjustment” on page

24.

10

Before starting the drive, ensure that all keys are in place

and all setscrews and all capscrews are tight. Check and

retighten all screws and retension belts after approximately

24 hours of service.

Adjusting:

1

Slack off belt tension if belts have been installed.

2

Loosen setscrews

D

.

3

Loosen but

do not remove

capscrews

E

.

4

Remove key

F

.

Note:

This key projects a small amount to provide a grip

for removing.

5

Adjust pitch diameter by opening or closing the movable

flanges by half or full turns.

Note:

Two-groove sheaves are supplied with both grooves

set at the same pitch diameter.

To provide the same pitch diameter for satisfactory

operation, move both movable flanges the same number of

turns. Do not open sheaves more than five turns for

A

belts

or six turns for

B

belts.

6

Replace key

F

.

7

Tighten setscrews

D

and capscrews

E

8

If belts have been installed, readjust belt tension. If belts

have not been installed, install them and adjust belt tension.

Do not force belts over grooves.

See “Fan Drive Belt

Adjustment” on page 24.

9

Before starting the drive, ensure that all keys are in place

and all setscrews and all capscrews are tight. Check and

retighten all screws and retension belts after approximately

24 hours of operation.

MVP Variable Speed Sheaves

Mounting:

1

Verify both driving and driven sheaves are in alignment and

the shafts are parallel. The centerline of the driving sheave

must be in line with the centerline of the driven sheave. See

Figure 34.

2

Verify that all setscrews are torqued to the values shown in

Table 14 before starting drive. Check setscrew torque and

belt tension after 24 hours of service.

Adjusting:

1

Adjust motor base forward to release belt tension. Remove

the belts for easier adjustment.

2

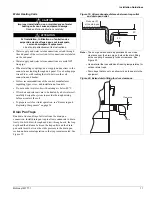

Loosen, but do not remove both of the locking setscrews

A

in the outer locking ring by using a hex key or torque

wrench with a hex bit.

3

Adjust sheave to desired pitch diameter by turning the outer

locking ring. Use a spanner wrench or drift inserted into the

three holes that are located 120° apart on the ring.

4

Any pitch diameter can be obtained within the sheave

range. One complete turn of the outer locking ring changes

the pitch diameter 0.233".

5

Do not open sheaves more than the following

•

Do not open

B

sheaves more than 4 3/4 turns for the

A

belts or 6 turns for the

B

belts.

•

Do not open

C

sheaves more than 9 1/2 turns.

•

Do not open

5V

sheaves more than 6 turns.

•

Do not open

8V

sheaves more than 8 turns.

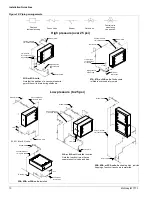

Figure 33: LVP type sheave adjustment

Section A-A

Section A-A

A

B

C

D

E

F

D

E

A

E

C

F

D

A

A

Содержание Skyline IM 777-1

Страница 32: ...30 McQuay IM 777 1...

Страница 33: ...McQuay IM 777 1 31...

Страница 34: ...32 McQuay IM 777 1...

Страница 35: ......