Installation and Operational Instructions for BRE250 and BRE400

ROBA-stop

®

-M brake Type 891.

0_ _._

Sizes 250 and 500

(E070 09 203 001 4 EN)

31/10/2019 TK/MW

Chr. Mayr GmbH + Co. KG

Eichenstraße 1, D-87665 Mauerstetten, Germany

Phone: +49 8341 804-0, Fax: +49 8341 804-421

Page 19 of 20

your reliable partner

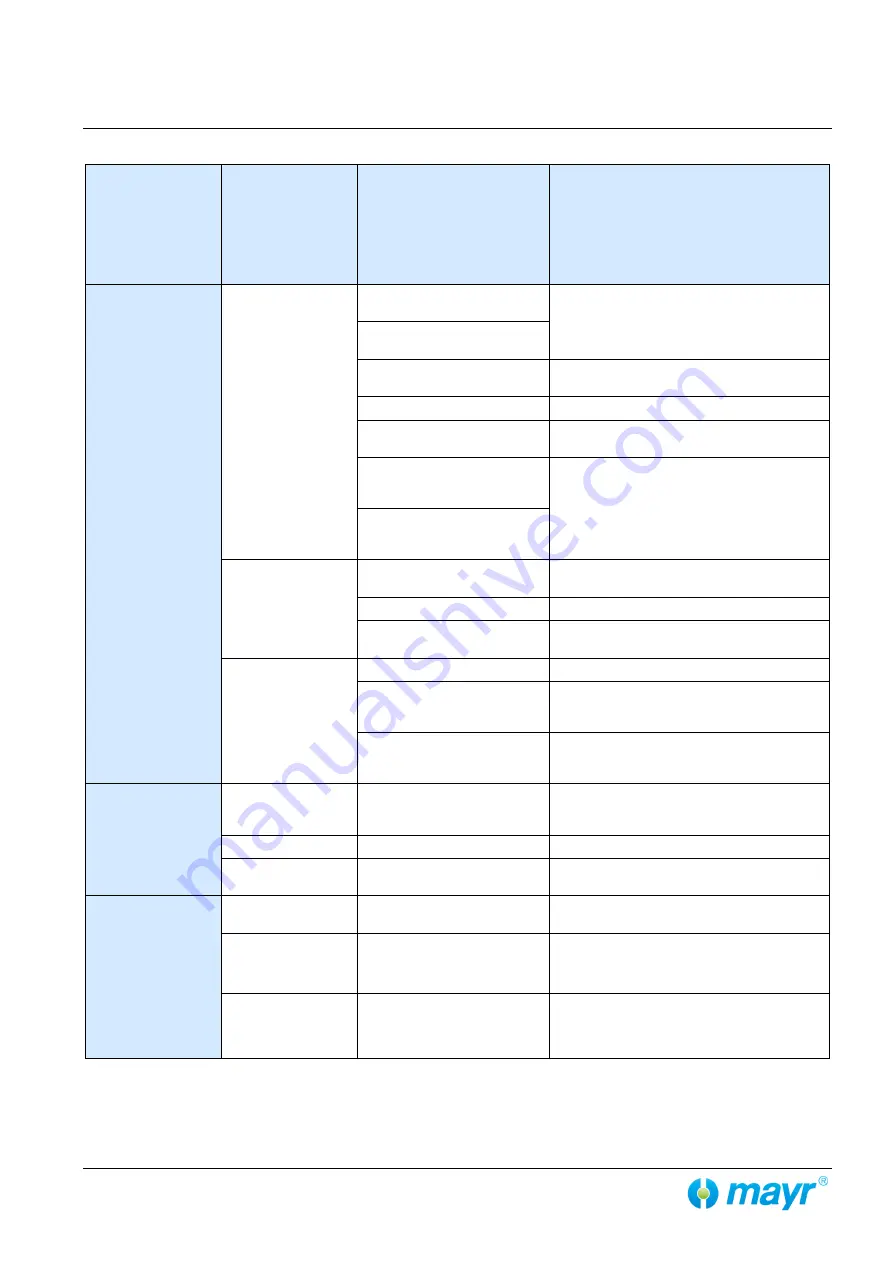

Malfunctions / Breakdowns

Malfunction

Result of Malfunction

Possible Causes

Solutions

The brake must always be dismantled in order

to remove damage and malfunctions.

Damaged parts must be replaced in order to

solve the respective problem.

The brake must be cleaned before re-installa-

tion.

The brake does not

release completely;

permanent grinding of

the rotor

The axial flexibility of

the rotor is limited;

rotor is jammed axially

Incorrect tolerance constellation

on the shaft-hub connection

Check tolerances

Tolerance errors

on the key connection

Broken hub due to installation

error when mounting

Suitable mounting method

Poor shaft quality

Check the shaft quality

Poor key

dimensioning

Carry out a key calculation

Contamination of the hub or rotor

toothing

due to abraded or worn particles Check the hub and rotor toothing; maintain suitable

maintenance intervals

Wear, damage,

deformation or breakage

of the hub and rotor toothing

Wiring error on the

brake

Incorrect voltage,

no DC voltage

Check voltage,

observe the wiring guidelines

Defective electrical wiring

Check electrical wiring

Defective coil, coil is electrically or

thermally overloaded

Check coil capacity;

check insulation resistance

Air gap too small in re-

leased condition

Due to installation

Air gap inspection

Penetration of foreign bodies into

the brake, in particular

magnetisable particles

Check the brake interior for dirt and clean it

Excessive component tempera-

tures;

temperature expansion

Temperature inspection

Increased friction

work; brake grinds

Excessively long en-

gagement times

Load accelerates the drive line

during the brake engagement

time

Check for correct wiring, switching times and di-

mensioning

Drop in braking torque

Excessive wear on the rotor

Wear inspection; replace the rotor

Motor starts up against

closed brake

Excessive brake attraction times

Check for correct wiring, switching times; check di-

mensioning; check motor controls

Component breakage

Operating conditions

Oscillations, vibrations, overload,

unpermittedly high speeds

Check operating conditions and dimensioning

Ambient influences,

temperature, fluids,

media, corrosion

Friction linings sticking, settling or

swelling; changes in friction lining

friction behaviour

Check protection against environmental influences

Deviations,

adjustment dimensions,

screw tightening

torques

Brake securement,

hand release, actuation lever,

screws

Check the guidelines and values according to the

information in the Installation and Operational In-

structions