Chapter 1 Product inspection and installment

8

1.4

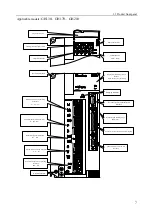

Servo driver installation

1.4.1

The environmental conditions for installation

Since the environment conditions for servo driver installation have the direct influence

to the normal function and service life of the servo driver, therefore the environment

conditions must be conformed to the following conditions:

Ambient temperature: 0 to 40

℃

; ambient humidity: less than 80% (no dew).

Storage temperature: -40 to 50

℃

; Storage humidity: less than 93% (no dew).

Vibration: less than 0.5G.

Preventive measure shall be taken against raindrop or moist environment.

Avoid direct sunlight.

Preventive measure shall be taken against corrosion by oil mist and salinity.

Free from corrosive liquid and gas.

Preventive measure shall be taken against entering the servo driver by dust, cotton fiber and

metal tiny particle.

Keep away from radioactive and inflammable substances.

When several driver installments in a control cubicle, for good ventilation please reserve

enough space around each driver, install fans to provide effective cooling, keep less than

40

℃

for long-term trouble-free service.

If there are vibration sources nearby (punch press for example) and no way to avoid it, please

use absorber or antivibration rubber filling piece.

If there is disturbance from interferential equipment nearby along the wirings to the servo

driver can make the servo driver misoperation. Using noise filters as well as other

antijamming measure guarantee normal work of the servo driver. However, the noise filter

can increase current leakage, therefore should install an insulating transformer in the input

terminals of power supply.

1.4.2

The method of installation

In order to get good cooling the servo driver should normally mount in vertical direction with

the topside upward.

For installing the servo driver, fasten the backboard of the servo driver with M5 screw bolt.

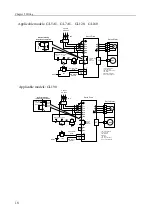

Reserve enough space around the servo drivers as shown in the reference diagram. In order

to guarantee the performance of the servo driver and the lifetime, please make the space as

full as possible.

To provide vertical wind to the heat sink of the servo driver should install ventilating fans in

the control cubicle.

Prevent the dust or the iron filings entering the servo driver when install the control cubicle.

Содержание EP3E Series

Страница 10: ......