19

1

1921 Slauson

A

ve. Santa Fe Springs, CA. 90670 (800) 227-41

16 F

AX (888) 771-7713

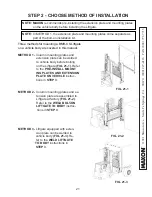

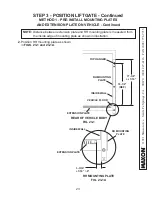

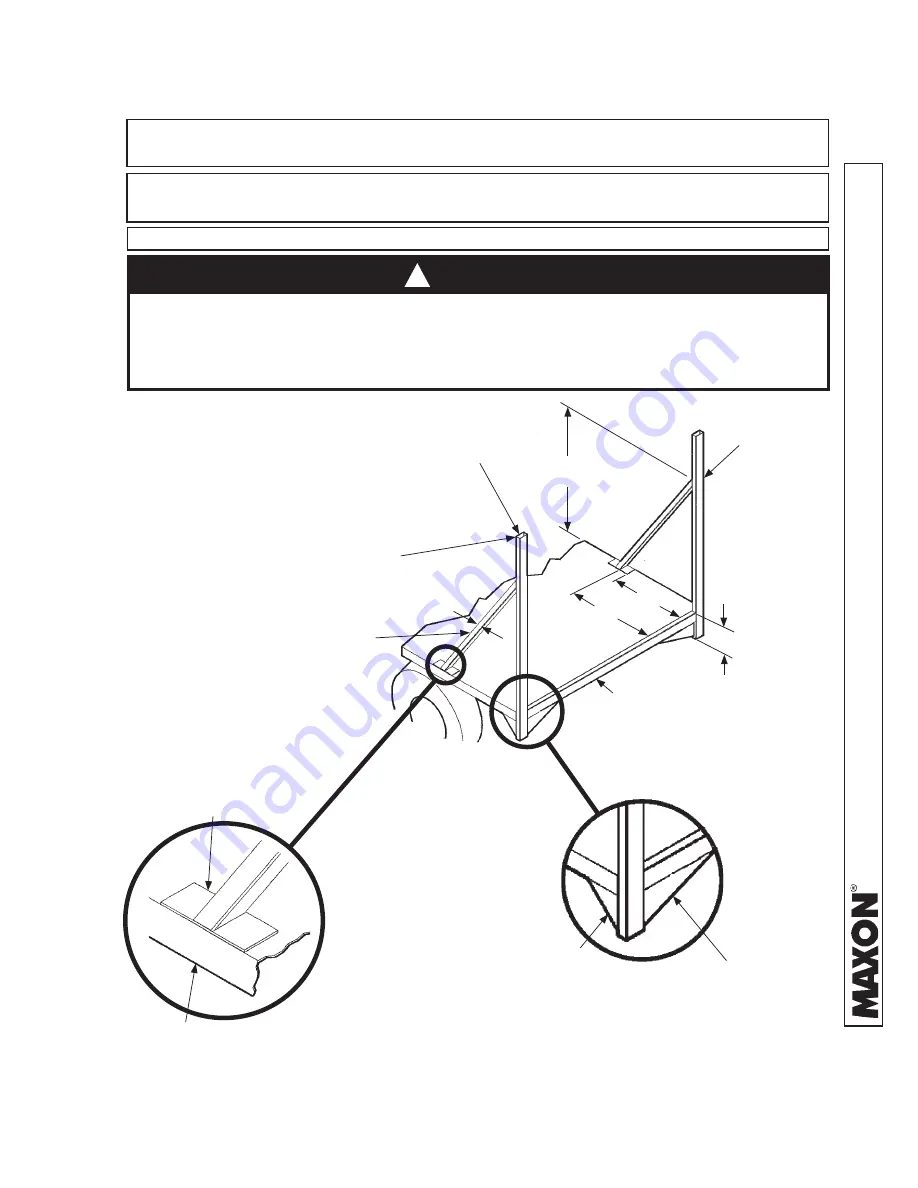

STEP 1 - PREPARE VEHICLE IF REQUIRED

1.

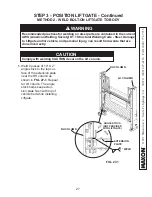

Fabricate framework, as shown

in

FIGS. 19-1A, -1B & -1C

, to

support Liftgate on a

fl

atbed ve-

hicle. Then, go to the next page

for welding instructions.

NOTE:

Materials for support framework are not provided with Liftgate.

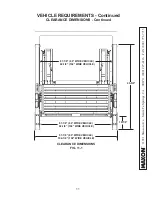

RECTANGULAR TUBING, 1/8” WALL

ASTM-A36 GENERAL PURPOSE

STEEL, 2” x 4” x 70” LG.

(QTY. 2)

RECTANGULAR TUBING, 1/8” WALL

ASTM-A36 GENERAL PURPOSE

STEEL, 2” x 4” x 85” LG.

(QTY. 2)

RECTANGULAR TUBING,

1/8” WALL, ASTM-A36

GENERAL PURPOSE STEEL

2” x 4” x 88” LG. (96”WIDE BODY)

2” x 4” x 94” LG. (102”WIDE BODY)

(QTY. 1)

60”

36”

Approx.

RIGHT HAND (RH)

SUPPORT

LEFT HAND (LH)

SUPPORT

2”

VEHICLE BODY

SIDE RAIL

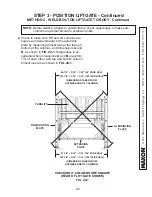

FLOOR PLATE,

1/4” THICK, ASTM-A36

GENERAL PURPOSE STEEL

4” x 10” LG.

(QTY. 2)

POSITIONING FLOOR PLATE

FIG. 19-1B

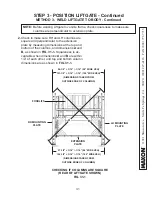

LOWER SUPPORT GUSSET,

1/4” THICK, ASTM-A36

GENERAL PURPOSE STEEL

8” x 8” LG. SIDES

(QTY. 2)

LOWER SUPPORT GUSSET,

1/4” THICK, ASTM-A36

GENERAL PURPOSE STEEL

8” x 16” LG. SIDES

(QTY. 2)

LIFTGATE SUPPORT

FRAMEWORK FOR FLATBED

FIG. 19-1A

POSITIONING GUSSETS

FIG. 19-1C

12”

(MAX. BELOW

BED HEIGHT)

32”

NOTE:

LH and RH supports must be perpendicular to level ground.

See VEHICLE

REQUIREMENTS, INSTALLED LIFTGATE.

NOTE:

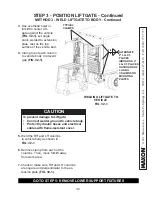

Perform the following step for

fl

atbed vehicle body only.

If vehicle body is

not a fl atbed, skip this step.

Recommended practices for welding on steel parts are contained in the current

AWS (American Welding Society) D1.1 Structural Welding Code - Steel. Dam-

age to Liftgate and/or vehicle, and personal injury can result from welds that

are done incorrectly.

WARNING

!

Содержание BMR-CS

Страница 103: ......