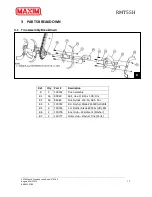

RMT55H

20195 South Diamond Lake Road, STE 100

Rogers, MN 55374

800.621-2789

19

Ref. Qty

Part #

Description

1

1

130761

SLASHER TINE SET (HD)

2

1

359341

BRACKET,LOW B/GUARD-PAINT

3

3

87373

NUT, CLIP, 1/4-20, 0025-015, BLACK

4

1

359343

BRACKET,UPPER B/GUARD-PAINT

5

2

336678

BRACE. HANDLE BAR - PAINT

6

3

80027

BOLT,HHCS,1/4-20 X 1/2,GR5,ZINC

7

1 MX-130694

R.H. HANDLE ASSY -PAINT

7.1

1

313786

HANDLE GRIP, 1

7.2

1

87372

POST, BINDING, 0.25 X 1.25, ZINC

7.3

1

87425

BOLT, TRUSS, #10-24 X 5/16, ZINC

7.6

1 336683-SD

CLUTCH LEVER – PAINT, W/DECAL

7.7

1 130688-SD

TUBE, HANDLE, TILLER, W/DECAL

8

1

461469

PIN, DEPTH BAR ADJ.

9

1 MX-130695

L.H. HANDLE - PAINT

9.2

1

313786

HANDLE GRIP, 1

9.3

1 130688-SD

TUBE, HANDLE, TILLER,

10.1

1

130683

CROSS BRACE - PAINT (RMT55H)

10.2

1

336919 DECAL, HANDLE BRACE, COMMERCIAL

12

1

130733-

RMT55H

GUARD, BELT, W/DECALS

13.1

1 MX-132183

HONDA ENGINE, 5.5 H.P. HORIZ.

SHAFT

13.2

1

104078

MUFFLER DEFLECTOR

13.3

1

162067

BELT GUIDE - PAINT

13.6

2

87437

8 X 1/4 FLG HEAD SCREW AB

13.7

2

80196

5/16 LOCK WASHER - ZINC

13.8

2

86667

BOLT, HHCS,5/16-24 X 3/4,GR5,ZINC

14

1 MX-162045

ASSY, YOKE

14.1

1

162033

MOUNT-YOKE REAR WHEELS

14.2

2

162065

WHEEL, 10" X 1.75" (H/D)

14.3

1

461468

PIN, COTTER, 7/64 X 1.00, ZINC

14.4

1

461467

PIN-L-1/2 X4 Zn-CLR

14.5

5

80207

WASHER, FLAT, 1/2 SAE, ZINC

14.6

1

359362

SPRING, 0.055 WDIA, 0.579 ID, 1.575

14.7

2

86453

CAP, PUSH, 1/2 ID, ZINC

15

1

500003

R. H. FRAME RAIL

17

1

130400

TRANSMISSION, COMPLETE PAINT

18

1

162069

IDLER SHAFT, TILLER

19

1

338009

IDLER PULLEY, 2-3/4" X 3/8"

Ref. Qty

Part #

Description

20

2

359335

SPACER, TRANS. -FORM<7/8">

21

1

359325

LEVER, IDLER - CUT/PUNCH

22

2

130701

HITCH CASTING

23

1

336686

DEPTH BAR - PAINT

24

1

87433

SPRING, .055 WDIA, 0.75 ID, 1.5-0.35

LENGTH

25

3

87422

3/8-24 NYLOCK NUT

26

1

87270

3/8-24 HEX NUT

27

1

336671

PULLEY, 9" X 5/8"

28

1

87269

3/16 X 3/4 WOODRUFF KEYK9N

29

3

87268

5/16-18 X 5/16 SETSCREW ZN

30

1

271686

2 X 3/4 C/SHAFT PULLEY

31

1

86615

KEY-SQUARE 3/16 X 1-BR

32

8

80205

5/16 SAE FLAT WASHER - ZINC

33

11

86101

5/16 NYLON LOCK NUT

34

5

80045

BOLT, HHCS, 5/16-18 X 2 3/4, GR5,

ZINC

35

1

87282

BOLT,HHCS,5/16-18 X 2.25,GR5,ZINC

36

4

80039

5/16-18 X 1-3/4 HEX SCREW GR 5-

37

1

272201

BELT, 4L51

38.1

4

80031

1/4-20 X 1-1/2 HEX SCREW GR 5-ZINC

38.2

6

85128

1/4" NYLON LOCK NUT

38.3

1

87416

SPRING, EXTENSION

38.4

1

162041

CLUTCH CABLE ASSEMBLY

38.5

2

87274

5/16-18 X 3 3/4 CAP SCREW

38.6

4

80205

5/16 SAE FLAT WASHER - ZINC

38.7

4

86101

5/16 NYLON LOCK NUT

38.9

2

87374

P-CLIP, 3/8 X 9/16, GAL

38.10 4

461466

PIN, CLEVIS, 3/8, 2-1/4, ZINC

38.11 4

461468

PIN, COTTER, 7/64 X 1.00, ZINC

38.12 2

86115

5/16-18 X 1-1/4 HEX SCREW GR 5-ZINC

38.15 1

790471

HOLDER, MANUAL, SMALL

38.18 2

85015

BOLT, HEX, 1/4-20 X 2, GR 5, ZINC

38.19 1

80193

¼-20 x ½ THRD CUT HEX - ZINC

39

1

80037

5/16-18 X 3/4 HEX SCREW GR 5-ZINC

44

1

80212

1/4 USS FLAT WASHER - ZINC

46

1

500002

L.H. FRAME RAIL

47

1

359853

ENGINE GUARD

48

2

313786

HANDLE GRIP, 1

49

1

80206

WASHER, SAE 3/8 ZINC