Series TSTM-DC Test Stands

User’s Guide

10

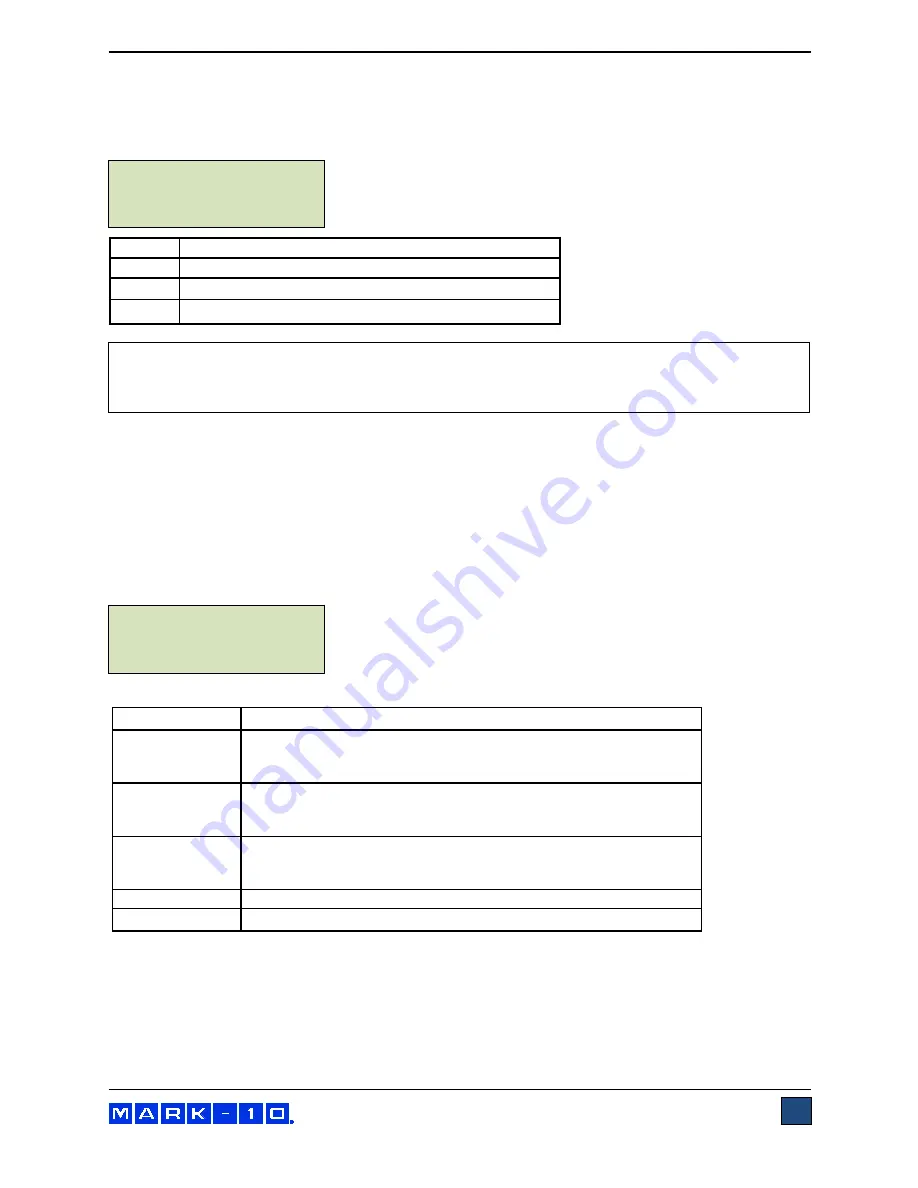

Default setting: off

Available settings: off, on

Label

Description

+ or –

Cycles through the available settings

ENTR

Returns to the Test Function Setup menu

ESC

Exits the function without saving changes

Note:

If

AUTO RETURN

is turned

on

,

CYCLING

is automatically turned

off

and the

KEYS

function is

automatically set to

MAINTAINED

mode. See following pages for details on the

CYCLING

and

KEYS

functions.

4.3 Cycling (CYCLES)

This setting allows the user to configure the number of CW and CCW cycles through which the torque

plate will sequence. One cycle consists of the torque plate moving to a limit (torque set point,

angle/degree limit, or various event completions in the M7I,) whichever occurs first, at the specified

speed, stopping for the specified amount of dwell time, and returning to the other limit at the specified

speed.

Default setting: 00000 (off)

Available settings: 00000 – 99999

A U T O R E T U R N o f f

E S C − + E N T R

C Y C L E S : 0 0 0 0 0

E S C − + E N T R

Label

Description

+

Increases the number of cycles in increments of 1. Holding down

+

will increment at an increasingly faster rate. If 99999 is reached

the next number will be 00000 and continue incrementing.

–

Decreases the number of cycles in increments of 1. Holding down

–

will decrement at an increasingly faster rate. If 00000 is reached

the next number will be 99999 and continue decrementing.

Press and hold

+ and –

simultaneously

If pressed and held for 2 seconds or longer the number of cycles

will change to 0.

ENTR

Returns to the Test Function Setup menu

ESC

Exits the function without saving changes

Содержание TSTM-DC

Страница 1: ...Series TSTM DC Motorized Torque Test Stands User s Guide...

Страница 23: ...Series TSTM DC Test Stands User s Guide 23 10 DIMENSIONS in mm TSTM DC...

Страница 24: ...Series TSTM DC Test Stands User s Guide 24 TSTMH DC CONTROL PANEL...

Страница 25: ...Series TSTM DC Test Stands User s Guide 25 NOTES...