Operator’s Manual

Self-Propelled Scissor Lift

Version1

38

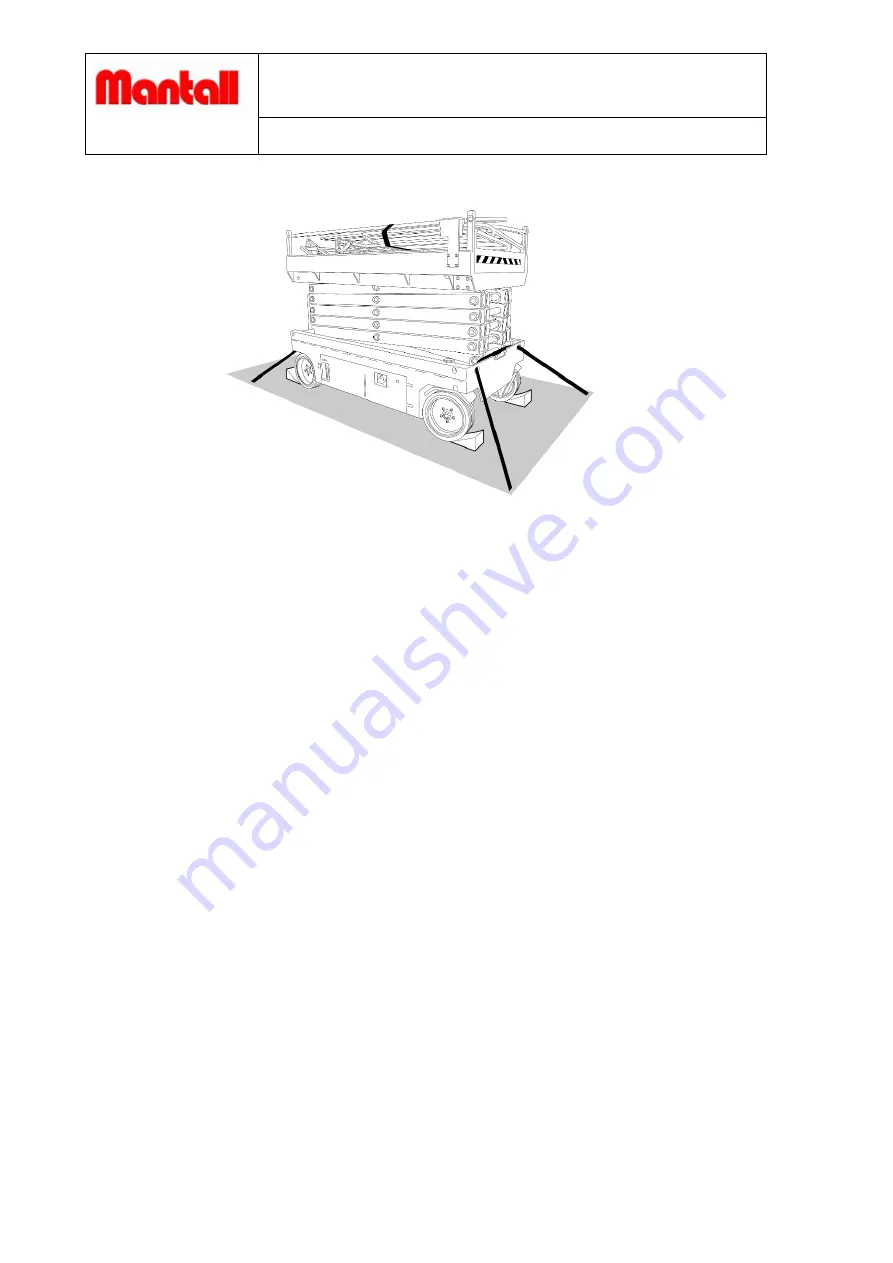

10.2 Securing the Machine to a Transport Vehicle

1. Put the machine in the correct position on the transport vehicle.

2. Chock the machine wheels.

3. Retract and secure the extension platform.

4. If necessary, fold down the platform guard rails (see Fold Down of the Platform Guard Rails on

page 33) and secure them with straps.

5. Inspect the entire machine for loose or unsecured items.

6. Turn the key switch of the ground control panel to the off position and remove the key before

transporting.

7. Use the tie-down points on the chassis to secure the machine to the transport vehicle.

8. Use a minimum of two chains or straps of sufficient load capacity.

11

Maintenance

11.1 Check the Hydraulic Oil Level

Maintaining the hydraulic oil at the proper level is essential for sufficient machine operation. Improper

hydraulic oil levels can damage hydraulic components. Daily checks allow the inspector to identify

changes in oil level that might indicate hydraulic system issues.

Note

: Perform this procedure with the machine level, on a flat surface and the platform in the

stowed position.

1. Visually inspect the hydraulic oil level sight gauge located on the side of the hydraulic oil tank.

➢

Result

: The hydraulic oil level should be between the 2 marks on the sight gauge.

2. Add hydraulic oil if necessary. Do not overfill.

11.2 Add Hydraulic Oil

1. Open the ground control panel side cover.

2. Remove the fill cap from the hydraulic oil tank.

3. Add hydraulic oil until the oil level is between the 2 marks on the hydraulic oil level sight gauge.

Hydraulic oil specifications

Use of hydraulic oil: 32# Anti-wear hydraulic oil.