SEDM-L - Smoke extraction damper - multi

Page 38

Version 2022-12-20

TPM 157/22

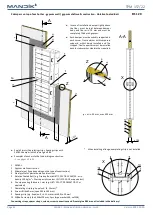

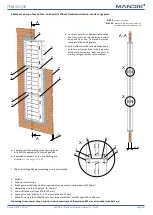

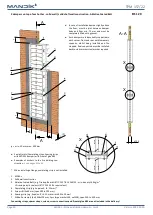

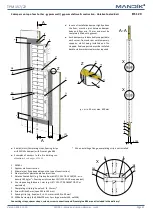

A-A

X

Y

≥

1

0

0

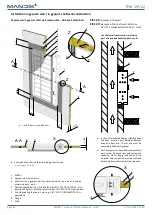

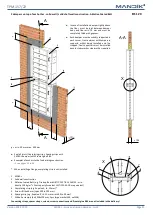

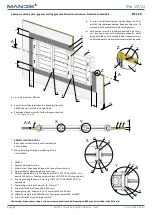

Connecting straps, spacer straps, screws, screw connections and Promat glue K84 are not included in the delivery!

*

RESPECT JOINT POSITION !

Bolts and nuts shall not prevent free rotation

on the blades.

** When installing a flange, overplating strip is

not installed.

■

Seal all joints (Overplating strips, Spacing strips with

SEDM-L damper) with Promat glue K84.

■

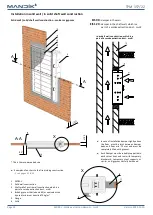

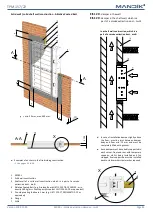

Examples of anchors to the fire dividing construction

■

In case of installation damper tightly above the floor,

must be joint between damper body and floor min. 75

mm and must be completely filled with gypsum.

■

Each damper must be suitably supported in each cor-

ner, front and rear with temporary supports, whilst

being Installed and fire stopped, final supporters must

be installed back to studs work or steel work as required.

y

= min. 30 mm, max. 400 mm

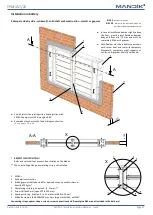

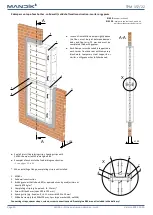

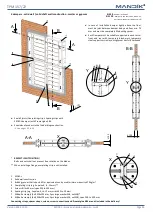

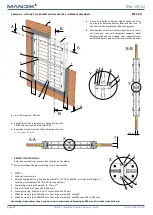

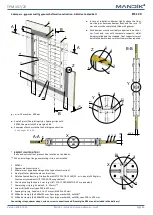

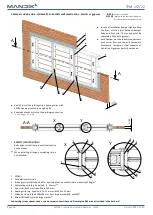

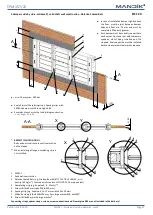

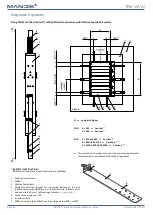

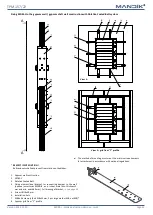

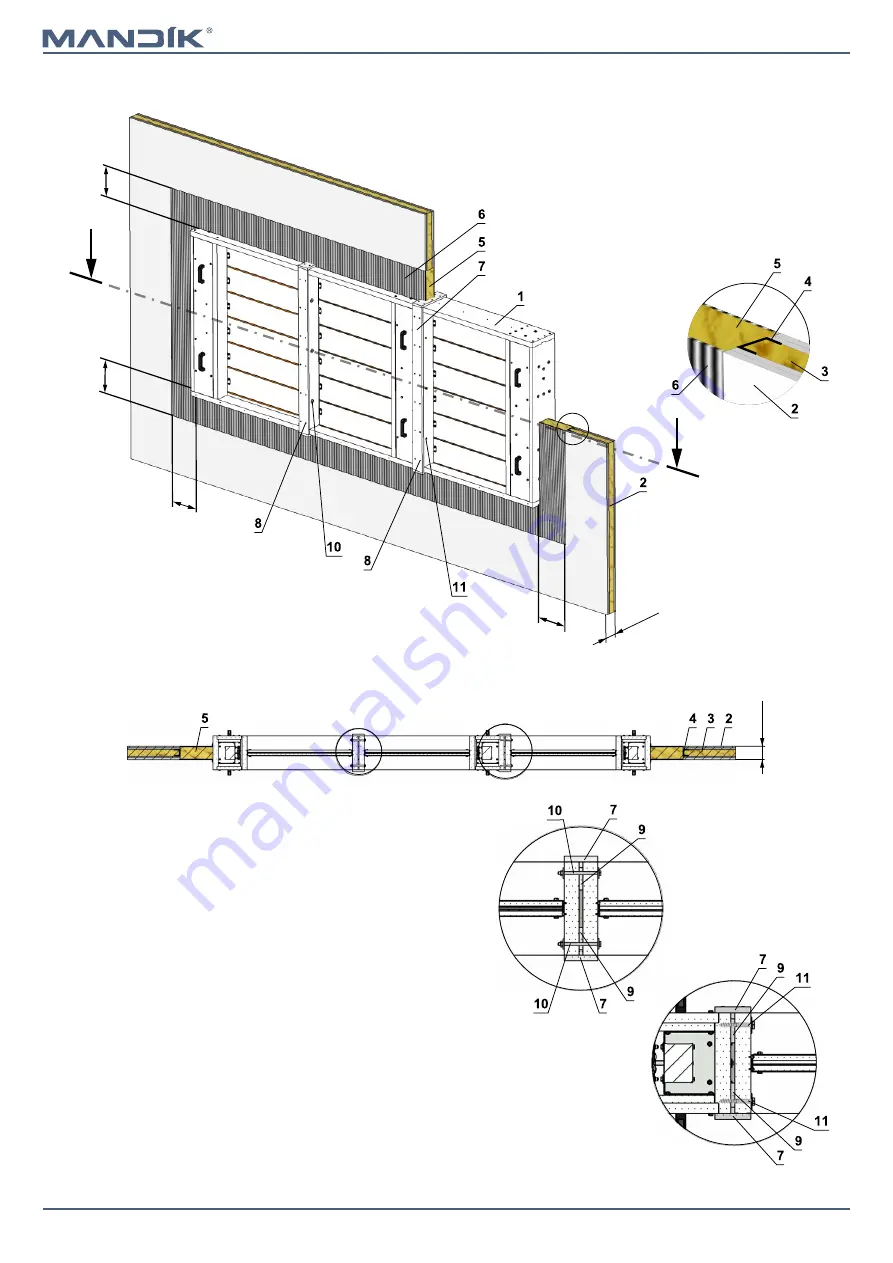

3 dampers side by side - gypsum wall / gypsum shaft wall construction - Ablative Coated Batt

EIS 120

X

Y

Z

A

y

y

y

≥ 1

00

y

Z

A

1

SEDM-L

2

Gypsum wall construction

3

Mineral wool (type depending on the type of construction)

4

Steel profile for plasterboard constructions

5

Ablative Coated Batt (e.g. Firestop Board HILTI CFS-CT B 1S 140/50 - min.

density 140 kg/m

3

+ Firestop acrylic sealant HILTI CFS-S ACR or equivalent)

6

Fire stop coating thickness 1 mm (e.g. HILTI CFS-CT, PROMASTOP-CC or

equivalent)

7

Overplating strip (e.g. Supalux-S, th. 15 mm) **

8

Screw UNI 4x40 mm (span 200 to 250 mm)

9

Spacing strip (e.g. Supalux-S, th. 12 mm, width 40 to 50 mm)

10 M8 bolt assemply (bolt M8x105 mm, 2 pcs large washer M8, nut M8)*

11 Screw UNI 6x80 mm with large washer*