SEDM-L - Smoke extraction damper - multi

Page 32

Version 2022-12-20

TPM 157/22

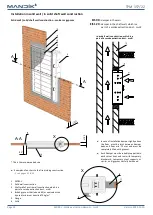

A-A

X

≥ 100

■

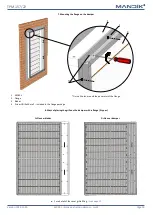

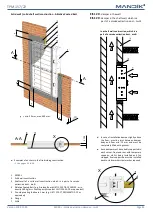

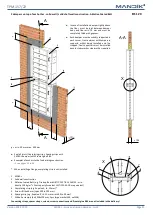

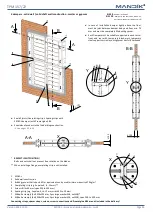

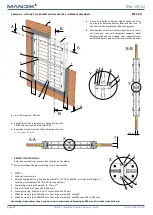

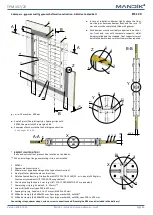

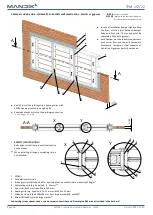

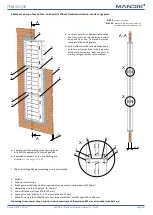

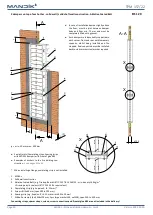

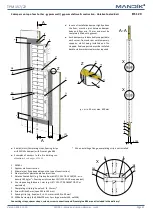

In case of installation damper tightly above

the floor, must be joint between damper

body and floor min. 75 mm and must be

completely filled with gypsum.

■

Each damper must be suitably supported in

each corner, front and rear with temporary

supports, whilst being Installed and fire

stopped, final supporters must be installed

back to studs work or steel work as required.

Connecting straps, spacer straps, screws, screw connections and Promat glue K84 are not included in the delivery!

* When installing a flange, overplating strip is not installed.

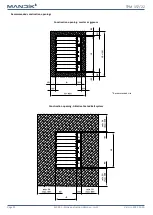

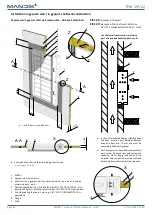

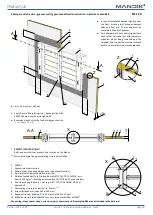

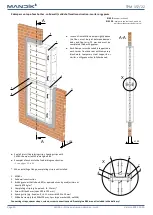

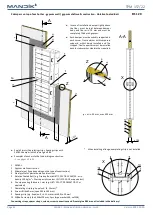

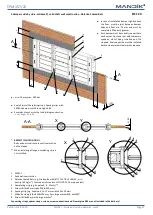

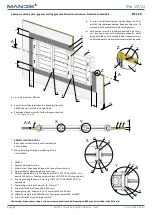

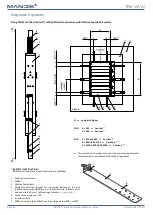

2 dampers on top of each other - gypsum wall / gypsum shaft wall construction - Ablative Coated Batt

y

= min. 30 mm, max. 400 mm

EIS 120

A

A

y

y

y

y

≥ 1

00

Z

Z

X

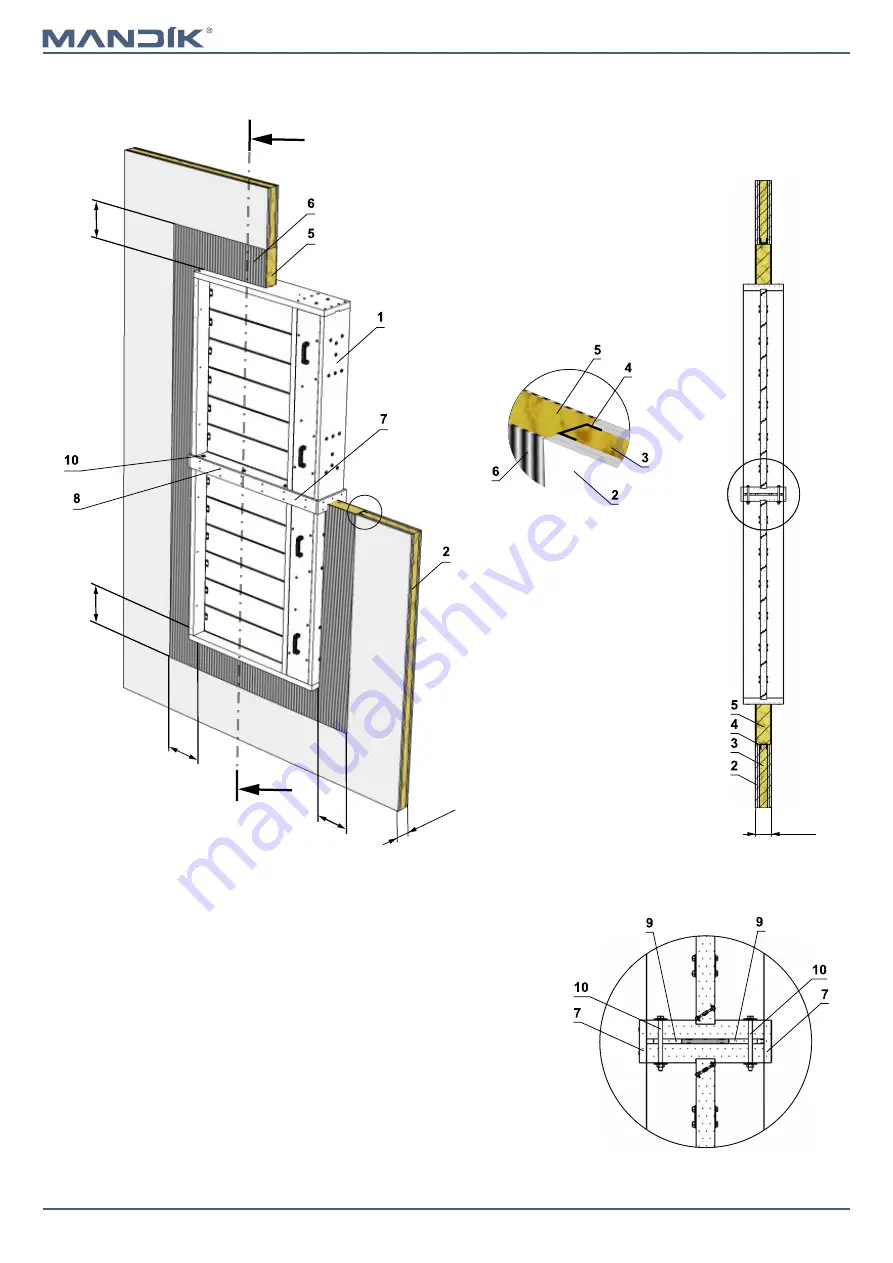

1

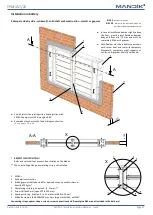

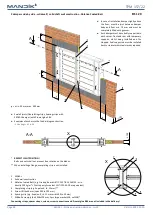

SEDM-L

2

Gypsum wall construction

3

Mineral wool (type depending on the type of construction)

4

Steel profile for plasterboard constructions

5

Ablative Coated Batt (e.g. Firestop Board HILTI CFS-CT B 1S 140/50 - min.

density 140 kg/m

3

+ Firestop acrylic sealant HILTI CFS-S ACR or equivalent)

6

Fire stop coating thickness 1 mm (e.g. HILTI CFS-CT, PROMASTOP-CC or

equivalent)

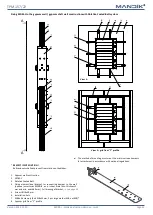

7

Overplating strip (e.g. Supalux-S, th. 15 mm) *

8

Screw UNI 4x40 mm (span 200 to 250 mm)

9

Spacing strip (e.g. Supalux-S, th. 12 mm, width 40 to 50 mm)

10 M8 bolt assemply (bolt M8x105 mm, 2 pcs large washer M8, nut M8)

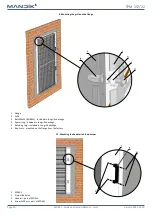

■

Seal all joints (Overplating strips, Spacing strips with

SEDM-L damper) with Promat glue K84.

■

Examples of anchors to the fire dividing construction