16

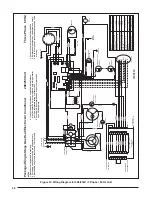

GAS SUPPLY AND PIPING

• All gas piping must be installed in compliance with

local codes and utility regulations. In the absence

of local codes the gas line installation must comply

with the latest edition of the National Fuel Gas Code

ANSI Z223.1 or CAN/CGA B149 Installation Codes.

• Some local codes require the installation of a manual

main shut-off valve and ground joint union external

to the furnace (Figure 9). The shut-off valve should

be readily accessible for service and/or emergency

use. Consult the local utility or gas supplier for

additional requirements regarding placement of the

manual main gas shut-off.

• The manifold pressure must be set to the appropriate

value for your installation. Refer to the Manifold

Pressure Adjustment section (page 20) for

adjustment instructions.

• Gas piping must never run in or through air ducts,

chimneys, gas vents, or elevator shafts.

• Compounds used to seal joints on gas piping must

be resistant to the actions of LP propane gas.

• The main gas valve and main power disconnect to

the furnace must be properly labeled by the installer

in case emergency shutdown is required.

• An 1/8 inch NPT plugged tap must be installed in

the gas line immediately upstream of the gas supply

connection to the furnace for use when measuring

the gas supply pressure. The plug should be readily

accessible for service use.

• A drip leg should be installed in the vertical pipe

run to the unit (Figure 9).

Optional Humidistat

An optional humidistat may be installed in the return

air duct for humidity control (when needed), maximum

system capacity and energy effi ciency. The humidistat

senses when humidity in the return air stream is above

a preset level and sends a signal to the motor to reduce

airfl ow. This allows more moisture to be removed until the

humidity level drops.

NOTE: The packaged heat pump unit is pre-programmed

for humidistat operation. Remove the jumper connector

between the two terminals marked HUM on the variable

speed board.

Install the humidistat in the return air duct as directed in

the installation instructions included with the kit. Wire the

humidistat through the low-voltage wire entrance in the

packaged heat pump unit to the quick-connect terminals

marked HUM. Wire the humidistat to open on rise in

humidity.

CAUTION:

To avoid personal injury or property damage,

make certain that the motor leads cannot

come into contact with any uninsulated metal

components of the unit.

Check all factory wiring to the units wiring diagram. Inspect

the factory wiring connections to be sure none loosened

during shipping or installation.

Ground

Joint

Union

Dripleg

Shut-Off Valve

with 1/8 NPT

plugged tap

Burner

Assembly

Manifold

Some utilities

require Shut-Off

Valve to be

4 to 5 feet

above floor

Automatic Gas Valve

(with manual shut-off)

Figure 9. Typical Gas Hookup - Right Side Entry