21

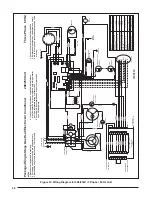

8. After the gas valve opens (30 seconds), the blower will

ramp to the selected airfl ow and continues to run.

9. When the thermostat has been satisfi ed, the W terminal

on the integrated control is de-energized.

10. The gas valve circuit is de-energized and the gas

vallve closes.

11. The inducer motor will continue to run for the post

purge period of 25 seconds.

12. The main blower will continue to run for the BLOWER

OFF delay of 135 seconds.

13. After the BLOWER OFF timer has been satisfi ed, the

integrated control de-energizes the main circulating

blower circuit.

Cooling Mode

1. On a call for cooling, the thermostat closes and applies

24 VAC to the green and yellow leads in the low voltage

area.

2. The green lead applies 24VAC to the G terminal of

the integrated control, energizing the main circulating

blower circuit at the cooling speed.

3. The yellow lead applies 24VAC to the contactor.

4. When the thermostat is satisfi ed, the contactor and

integrated control de-energize.

5. The circulating blower motor de-energizes after a 85-

90 second delay.

Fan Mode

1. On a call for fan operation, the thermostat applies 24

VAC to the green lead connected to the G terminal of

the integrated control.

2. The circulating blower is energized immediately at the

heating speed if 2-SPD is selected or fan only speed

if 3-SPD is selected on the control. NOTE: If a call for

heat occurs, the circulating blower de-energizes prior

to normal heating cycle.

EQUIPMENT MAINTENANCE

WARNING:

To avoid risk of electrical shock, personal injury,

or death, disconnect all electrical power to the unit

before performing any maintenance or service.

The unit may have more than one electrical supply.

Label all wires prior to disconnection when

servicing the unit. Wiring errors can cause

improper and dangerous operation

CAUTION:

Use care when removing parts from this unit.

Personal injury can result from sharp metal

edges present in all equipment of sheet metal

construction.

Proper maintenance is important to achieve optimum

performance from the system. The ability to properly

perform maintenance on this equipment requires certain

mechanical skills and tools. If you do not possess these

skills, contact your dealer for maintenance. Consult your

local dealer about the availability of maintenance contracts.

Routine maintenance should include the following:

CAUTION:

The unit should never be operated without a

fi lter in the return air system. Replace disposable

fi lters with the same type and size.

• Inspect, clean or replace air fi lters at the beginning of

each heating and cooling season, or more frequently

if required.

• Inspect the condensate drain and outdoor coil at the

beginning of each cooling season. Remove any debris.

Clean the outdoor coil and louvers as necessary using

a mild detergent and water. Rinse thoroughly with water.

• Inspect the electrical connections for tightness at the

beginning of each heating and cooling season.

• The blower compartment should be cleaned monthly

during the heating and cooling seasons to remove any dirt

and lint that may have accumulated in the compartment

or on the blower and motor. Buildup of dirt and lint on

the blower and motor can create excessive loads on

the motor resulting in higher than normal operating

temperatures and possible shortened service life.

• Maintain heat exchanger and burners. The unit should

operate for many years without excessive scale buildup

in the heat exchanger, however, the heat exchanger, the

vent system, and the burners should be inspected and

cleaned (if required) by a qualifi ed serviceman annually

to ensure continued safe operation. Particular attention

must be given to identify deterioration from corrosion

or other sources.