R

epair

P 7 / 17

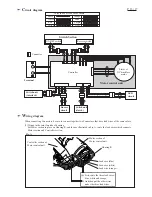

Fig. 25

Fig. 26

Fig. 27

Fig. 28

Fig. 29

Fig. 30

Fig. 31

Fig. 32

(2) Mount steel balls and cam B and cam A in the order of Fig. 25, Fig. 26, Fig. 27 and Fig.28.

(3) Before mounting, apply MAKITA grease N. No.2 to 13 pcs. of steel balls 3.0.

Assemble steel balls 3.0, flat washer 7 and torx counter sunk head screw M5x10 as illustrated in Fig. 29, Fig.30

and Fig. 31.

(4) Before mounting, apply MAKITA grease N. No.2 to threaded portion of spindle.

Assemble compression spring 19, flat washer 18 and adjust ring complete and lock nut 12

in the order of Fig. 31 and Fig. 32.

Steel balls 5

(3 pcs.)

Mount steel balls 5

to spindle.

Mount cam D to spindle

with aligning its 3 grooves

with steel balls 5.

Mount steel balls 4

to cam B.

Mount cam A.

Cam B

Steel balls 4

(3 pcs.)

Steel balls 3.0

(13 pcs.)

Mount steel balls 3.0

to cam A.

Mount flat washer 7

to cam A.

Pay attention, not to spot

the screw hole of spindle

with the grease, when

assembling steel balls.

Flat washer 7

Torx counter sunk

head screw M5x10

Apply here the

adhesive by 0.1CC,

before screwing.

After applying 0.1cc (3 drops) of

adhesive, "Lock tight 603" in the

screw hole, fasten flat washer 7

with torx counter sunk head

screw M5x10.

The fastening torque for the

screw is 8 - 10 N.m.

Compression

spring 19

Adjust ring

complete

Fig. 31

Lock nut 12

While pressing lock nut 12 strongly, turn torque adjust tool

clockwise. Then, lock nut M12 turns anti-clockwise

and fastened to spindle.

Cam A

Flat

washer 18