13

4. Operating Principles

4.1 SPEED

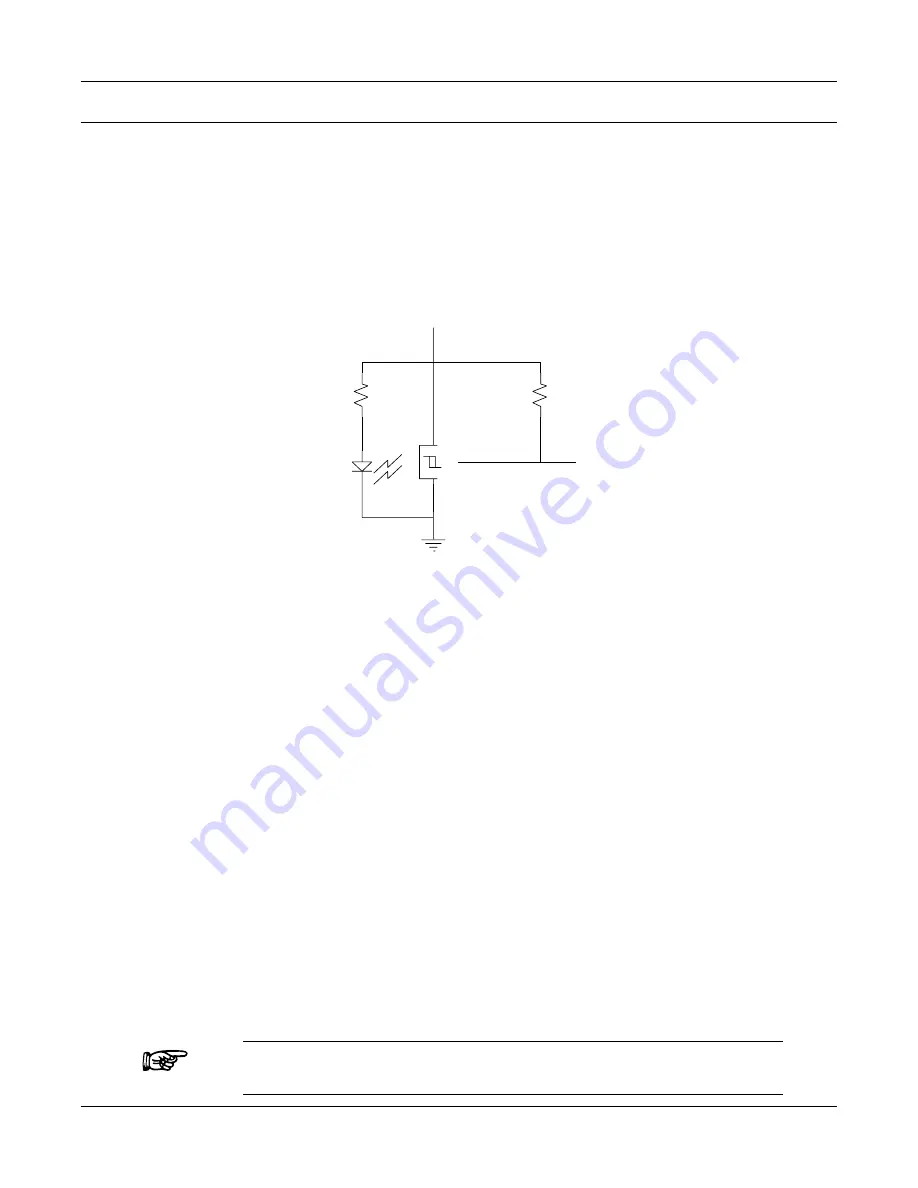

The dynamometer is shipped with an internal speed pickup and two cords: one terminating with a

2-pin plug for the brake power, the other is a 14-pin plug servicing an optical encoder. This encoder

consists of an infrared transmitter/receiver pair. On the end of the dynamometer shaft, positioned

between the LED and detector, is an optical disc with opaque and clear segments. Rotation of the

disc results in the detector generating a frequency of 60 pulses per shaft revolution.

R1

470

U1

4

OPB963

2

3

Fo

R2

200

5V (Pin 7)

5

(Pin 8)

(Pin 10)

1

Figure 4–1 Optical Encoder Circuit

4.2 TORQUE

Torsional force, acting upon the hysteresis brake, is produced by the test motor, and applied to the

brake’s rotor-shaft assembly. Whatever torque exists on the rotor-shaft, must be reacted upon equally

by the suspended brake-dial-weight assembly.

Since the brake assembly is imbalanced by the suspended weight attached to it, torsional force will

lift the weight. The graduated dial provides a readout value equal to this torque. Once the weights

are calibrated to match the dial graduations, the system accuracy becomes permanently fixed.

When torque is defined by a point on the radius of a weight, lifted in a circular motion, the scale

derivation is inherently a cosine function - thus, the nonlinear scale graduations.

4.2.1

t

orque

s

taBility

A major advantage in using a hysteresis brake as a loading means, is the ability to produce torque

essentially independent of speed. This permits very low speed and locked rotor torque testing.

Three factors have a minor secondary influence on hysteresis brake torque. They are:

• Hysteresis brake control current (

see Section 1.2.1

)

• Eddy current (

see Section 3.9

)

• Temperature rise (

see Section 3.10

)

Note:

Torque changes as a result of these influences are always part of the

actual torque measured—as applied to a test motor—and not errors.