Page 15

2.4.1. Coal Layout

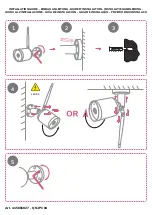

NOTE:

As the Burner Tray shape and therefore the coal layouts may vary,

ensure that the

principles

of the layouts below are followed.

The Burley Magiglo Custom 18 Plus comes

supplied with four different types of fire bed

refractories (i.e. ceramic coals and aeration

tubes). Each of these are packed in

separate bags which are appropriately

marked. The quantity supplied is dependent

on the size of the burner tray.

Proceed to carry out the coal laying

according to the following instructions and in

conjunction with the drawings on the

following pages.

1. Unpack the small square coals and place

them equidistant along the front edge of

the burner (as indicated in the figures

showing the

‘First Layer’

) taking care

not to cover the cross ignition slot or any

gas entry port holes.

2. Position the aeration tubes over the

shaded areas on the ceramic fibre base.

3. Unpack and carefully place the medium

square coals around the perimeter of the

burner tray so that they are touching

each other as indicated on diagram (as

indicated in the figures showing the

‘First Layer’

). Small gaps between coals

may be left on each side. Ensure that the

first coal on each side is set back a

minimum of ½" and no slots or port holes

are covered. There may be more

medium square coals than required. In

this instance only use sufficient coals to

go round the perimeter as indicated on

diagram.

4. Unpack the random coals and proceed

to bridge them across the aeration tubes,

starting with the middle row as shown on

diagram (as indicated in the figures

showing the

‘Second Layer’

). Then lay

the back row by bridging between

previously laid medium square coals and

aeration tubes. Next lay the front row by

bridging across the previously laid PC05

and the bridging coals in the middle row

making

sure

that

the

coals

are

adequately stable.

5. Proceed to lay a third layer of random

coals according to diagram (as indicated

in the figures showing the

‘Third Layer’

)

making sure that they are not packed

tightly together.

6. Place the coals above the pilot assembly

such that one end of the coal is resting

on pilot shield and the other on

previously laid random coals making

sure that the coals do not rest on the

pilot assembly.

7. Any extra random coals may be placed

at random on top of the third layer to

cover up large gaps in the layout. If the

fire is very deep, these coals could be

placed at the rear of the tray.

8. Small adjustments to the third layer may

be made once the fire is turned on to

alter the flame pattern if desired. A small

pair of tongs may be used to gently re-

position the coals.

9. It is recommended that the coals be left

alone once the desired flame pattern has

been achieved.

Constant moving of

the coals causes the coals to

disintegrate

and/or

cause

discolouration

.

WARNING:

Do not touch the

fire when it is alight. The fire will

remain very hot for a while after

extinguishing.

Содержание Custom 18 Plus

Страница 8: ...Page 4 This page is left intentionally blank...

Страница 26: ...Page 22...

Страница 30: ...Page 26 This page is left intentionally blank...