22

Product maintenance

Before and after each use, check the product and accessories (such as application tools) for wear and damage. If required,

exchange them for new ones as described in this instruction manual. Observe the technical requirements.

01

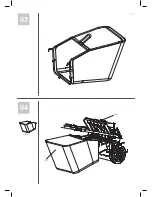

Underbody and cutting device

1. Keep the underbody and cutting device

(22) clean and free of debris. Remove clippings from the discharge chute.

2. Check all nuts and bolts periodically for tightness before operation. After prolonged use, especially in sandy soil conditions, the

cutting device will become worn and lose some of the original shape. The cutting efficiency will be reduced and the cutting device

should be replaced.

3. Keep the cutting device (22) sharp to ensure a good cutting performance. Replace a worn or damaged cutting device with a new

one of the same type or have it sharpened by a qualified specialist.

4. Loosen the blade tension bolt

(22e) anti-clockwise using a wrench and remove it together with a cone washer (22d), cutting

device (22), blade adaptor (22c) and key

(22b).

5. Replace the cutting device with a new one of the same type. Slide the key (22b) into the slot on the spindle (22a). Refit the blade

adaptor (22c), locking the cone washer (22d) and blade tension bolt (22e). Tighten the blade tension bolt clockwise with 35 N m

min, 40 N m max. to ensure safe operation of the product.

6. Lubricate the cutting device (22) after each use to prolong the life span of cutting device and product. Apply light machine oil

along the edge of the cutting device.

WARNING!

Wear protective gloves when working on the

cutting device and close to it! Use proper tools to remove

debris, e.g. a wooden stick! Never use your bare hands.

Always use original spare parts for replacement. The

cutting device must be replaced by an identification no. ref.

SMV 460206G

DO NOT attach any other type of cutting device!

The replacement of the cutting device should be done by

an experienced user. Rework or sharpening blades is not

recommended unless it is done by a repair service or a

similarly qualified specialist.

NOTE:

We strongly recommend jacking the product up when

performing inspection and work on the cutting device. Avoid

tilting the product in order to prevent fuel and oil leakages.

Содержание MLMP300HP46

Страница 2: ...Preparation 4 Assembly 11 Use 16 21 ...

Страница 11: ...11 02 01 4a x 2 4c 4b 4a 5 4b x 2 4c x 2 5 x 1 17a x 2 17a 17b 20 17b x 2 20 x 1 Assembly ...

Страница 12: ...12 03 04 19 x 1 18 19 ...

Страница 13: ...13 05 06 5mm 7 x 1 Max Min ...

Страница 14: ...14 Your product 1 2 3 4a 4b 4c 5 6 7 8 9 10 11 12 13 14 15 16 22a 22b 22c 22 22d 22e 17b 18 19 20 23 21 17a ...