3.Function

3.1 Adjusting function for the welding voltage and welding current

3.1.1 EWELDM253 supply the adjusting range at MIG/MAG as following,

±

±

Welding voltage : 14V

3V~28V

3V use the voltage adjusting knob

Welding current : 20A~250A use the current adjusting knob

3.1.2 EWELDM253supply the adjusting range at MMA as following,

Welding current : 10A~250A use the welding current knob on the panel.

3.2 Adjusting function of the Arc thrusting

It has the important function to select the proper Arc thrusting for improvement of the welding

line ,control the welding splash and the steady Arc. Normally,.

If the thrusting is low ,the arc is soft and splash .

If the thrusting is high,the arc is strong and high splash.

Use the arc thrusting continuously by the control knob on the front panel of EWELDM253.

4

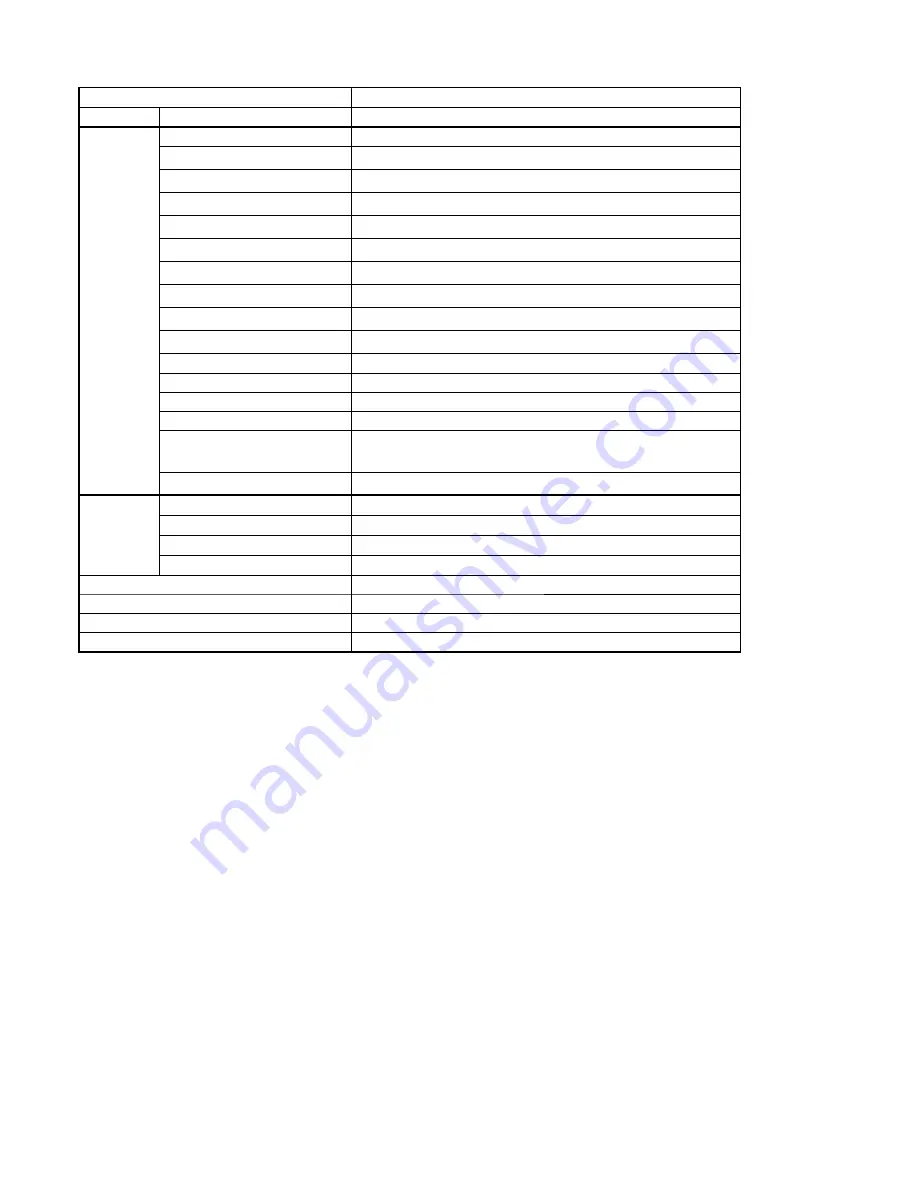

MODEL

EWELDM253

INPUT

Voltage

1xAC220V 50Hz/60Hz

DOUBLE

PULSE

MIG

PULSE peak Current

10~250A

PULSE peak Voltage

-5.0 ~ +5.0

Welding(base) Current

10~350A

Welding(base) Voltage

-5.0 ~ +5.0

mixed frequency

0.1-9.9Hz

mixed ratio

10-90%

Start(Initial) Current

10~250A

Start(Initial) Voltage

-5.0 ~ +5.0

crater-fill voltage

-5.0 ~ +5.0

crater-fill current

10-250A

Rated Duty Cycle

60%

Rated Output Current

250A

Wire Alloy Material

Fe,AlSi,AlMg,CrNi,Cu

Synergic MIG or BASIC MIG

only Synergic MIG

crater mode

2T( no Start Current & no crater current)

or 4T( no Start Current) or S4

(

special 4 step)

gas type

80%Ar+20%CO

2

(Fe,Cu) ; 100%Ar(AlSi,AlMg) ;98%Ar+2%CO

2

or O

2

(CrNi)

CO

2

or

MIG

inductance

1~10

Pre gas Flow Time

0~3s

Post gas Flow Time

0~20s

Wire Diameter

0.8,1.0,1.2(solid/flux)

Efficiency

≥

80%

Protection Class of enclosure

IP21S

Insulation class

F

Protection class of shell

fan cooling