9

GB

3. Starting up

3.1 Assembly in the container

Fasten the pump in the container with appropriate drum ad-

apters. Make sure that the container with the installed pump

is enough stably even in empty condition. This is of special

attention with small containers.

3.2 Mains connection

It is recommended to provide the motor with a protection switch

corresponding to the power consumption so as to prevent motor

destruction by overloading.

The electrical connection may only be carried out by

trained qualified personnel. Following regulations must

be observed:

- All works must only be carried out in voltage-free condition

of the motor.

If available, set the protection switch mounted to OFF.

- Mains voltage and frequency are as specified on the rating

plate.

- Dimension of the connecting cable must be adjusted to the

nominal current.

- The insulation of the connecting cable must be adjusted to

the environmental conditions.

3.3 Checking the direction of rotation

After the motor has been started, the direction of rotation of

the drive shaft must correspond to the rotation arrow on the

rating plate. If necessary, the motor terminal connections must

be reversed.

3.4 Connection to the pump tube

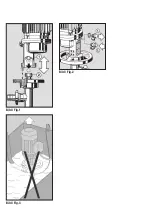

The motor is mounted on the pump tube. The upper cou-

pling

(Fig. 1 - Pos.1)

on the motor engaging in the coupling

(Fig. 1 - Pos. 2

) of the pump tube. The motor and pump

tube are then firmly connected by means of the handwheel

(right-hand thread).

When using plastic pump tubes, it is recommended to relieve

the pump tube of the motor weight by means of a support.

3.5 Mounting the vent valve

Before starting up the pump, replace screw plug

(Fig. 2 –

Pos. 1)

by vent valve

(Fig. 2 – Pos. 2)

. Thereafter, the motor

may no more be operated or stored in horizontal or inclined

position

≥

15° as oil will otherwise leak.

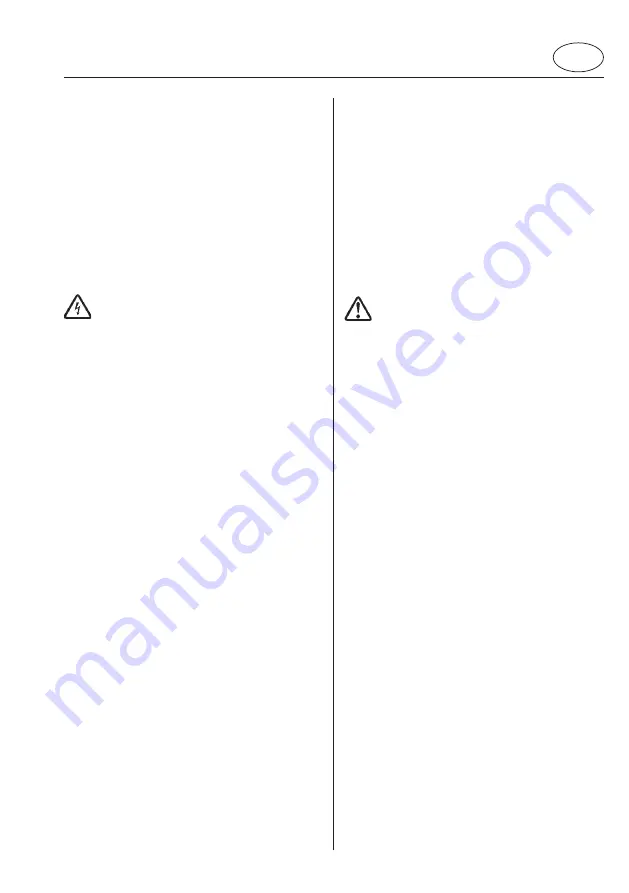

3.6 Maximum immersion depth

Care must be taken to ensure that the pump is not submerged

further than its discharge port

(see Fig. 3)

.

3.7 Uncontrolled re-start of the pump after

voltage drop

The motor is not equipped with a low voltage release.

After a voltage drop the pump may re-start

uncontrolled!

4. Maintenance

After 500 working hours:

Check gear oil level by means of an oil sight-glass situated

above the rating plate.

In case of oil deficiency, top up gear oil ESSO HDX or equivalent

oil HD SAE 20.

After 1000 working hours:

Change gear oil. Use 0.2 l gear oil ESSO HDX or equivalent

oil HD SAE 20.

Protect the environment: Handling and waste disposal of

mineral oils are subject to statutory provisions. Deliver waste

oil to an authorized point of acceptance.

5. Repairs

Repairs should only be made by the manufacturer or authorized

Lutz-dealers. Only use genuine Lutz spare parts.

Содержание B4/GT-750

Страница 2: ...Bild Fig 1 Bild Fig 2 Bild Fig 3...